DELEM DA-66S Profile-60S: מדריך לשימוש, התקנה ותפעול

בבחירת מערכות בקרה CNC ליישומי עיבוד מתכות, חשוב להבין את השימושים והפונקציות העקריים של מערכת הבקרה DELEM DA-66S Profile-60S. מערכת הבקרה המתקדמת הזו משמשת כרכיב מרכזי להבטחת פעילות יעילה ודقة במכונות כיפוף, ותורמת משמעותית לאוטומציה תעשייתית.

אם ברצונכם ללמוד כיצד מערכת זו מיטבת תהליכי ייצור ושיפור ביצועי הציוד, מאמר זה יפרט את הפונקציות שלה, שלבי ההתקנה ושיטות הפעלה, ויספק הנחייה ברורה בהחלטות שUpgrade לציוד או ללימוד מערכת CNC.

1. דרישות מערכת ל-Profile-60S

לפני השימוש ב- DELEM DA-66S Profile-60S, ודא שהמכשיר שלך עומד בדרישות החומרה והמתוכנה הבאות כדי להבטיח תפקוד מערכת יציב:

1.1 דרישות חומרה

• מחשב: מחשב משותף עם IBM;

• רזולוציה של המסך: רזולוציה מינימלית של 1920×1080

• נתיבים: לפחות נתיב USB אחד חינם (לתיקון תוכנה ולחיבור דונגל הרישיון).

1.2 דרישות תוכנה

• מערכת הפעלה: Windows 10;

• מנהל גרפי: מנהל גרפי תומך ב- OpenGL V3.3 או יותר.

2. משרד החוץ שלבי התקנה עבור תוכנת DELEM DA-66S Profile-60S

תהליך ההתקנה של תוכנת פרופייל-60S הוא פשוט. עקוב אחר מדריך שלב אחר שלב להשלמת ההפצה:

שלב 1: להכין את מדיה ההתקנה

הכנס את כונן ה- USB המיועד ל- Profile-60S למתקנה לתוך מנעול USB חינם של המחשב. המערכת תעלה באופן אוטומטי חלון של הדרג להתקנה; עקוב אחר ההזמנות על המסך כדי להוריד את קבצי ההתקנה הנדרשים למחשב המקומי. אם הקוסם האוטומטי לא מופיע, פתח ידנית את ספרית כונן USB כדי לאתר את קבצי ההתקנה.

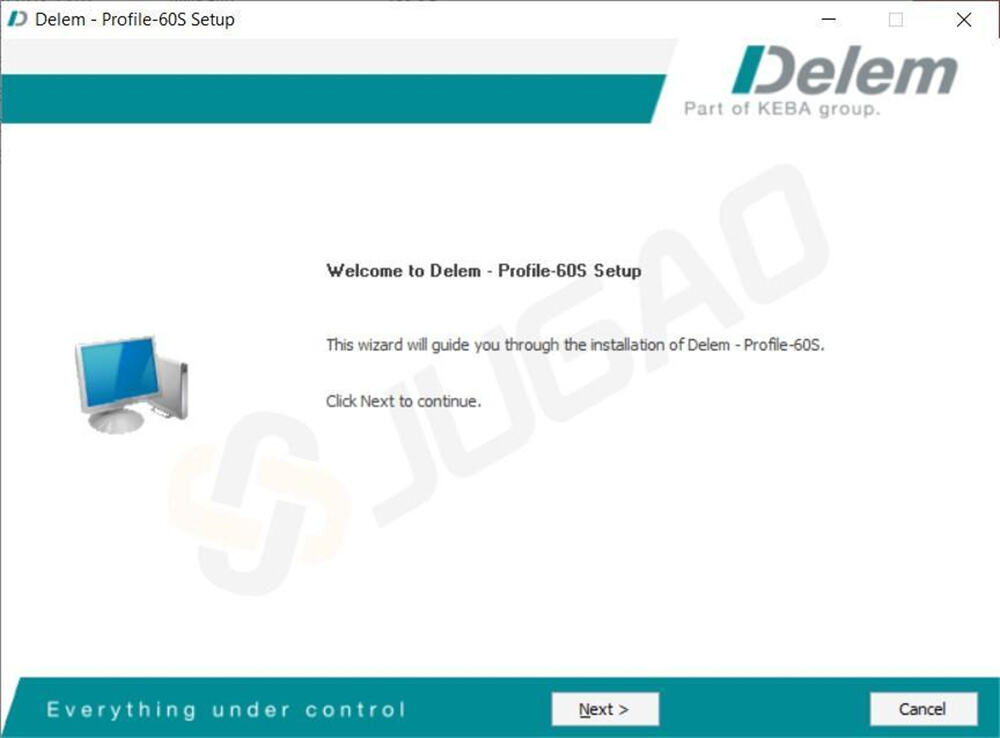

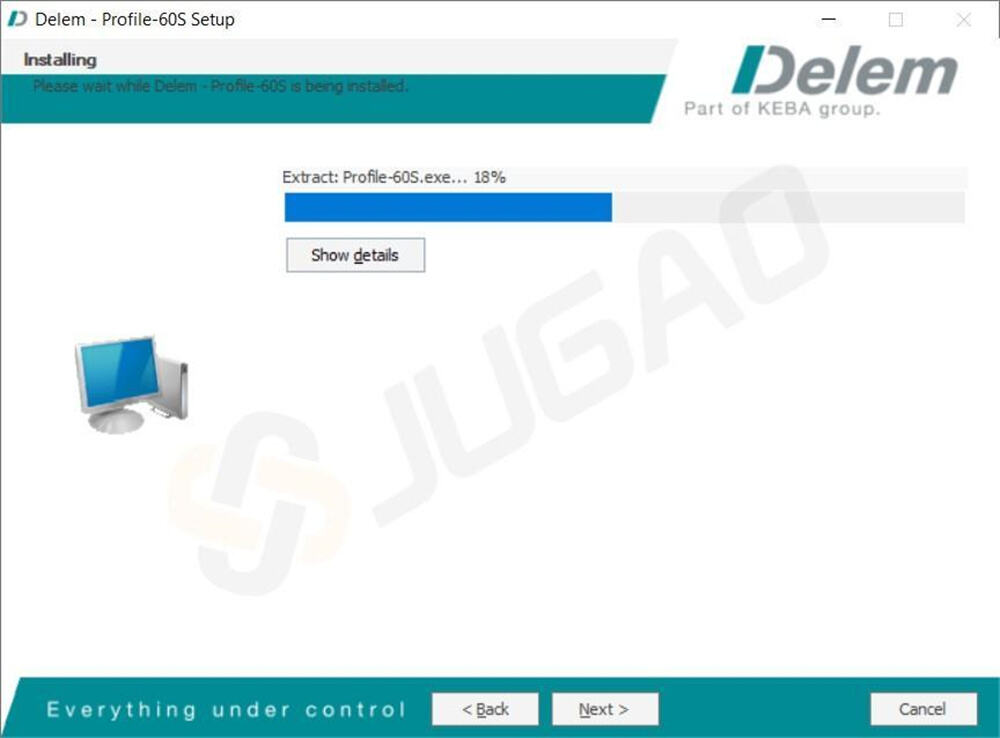

שלב 2: להפעיל את התוכנה להתקנה

• אם חלון הדרג להגדרה אוטומטית מופיע באופן נורמלי, לחץ על "באחרונה" כדי להתחיל את ההתקנה;

• אם לא מופיע חלון אוטומטי, מצא את קובץ ההתקנה בשם בפורמט "Delem.Profile-60S.setup.Vx.y.z.exe" בדחף ההתקנה של USB, והדפד-קליק על הקובץ הזה כדי להפעיל את תכנית ההתקנה באופן יד

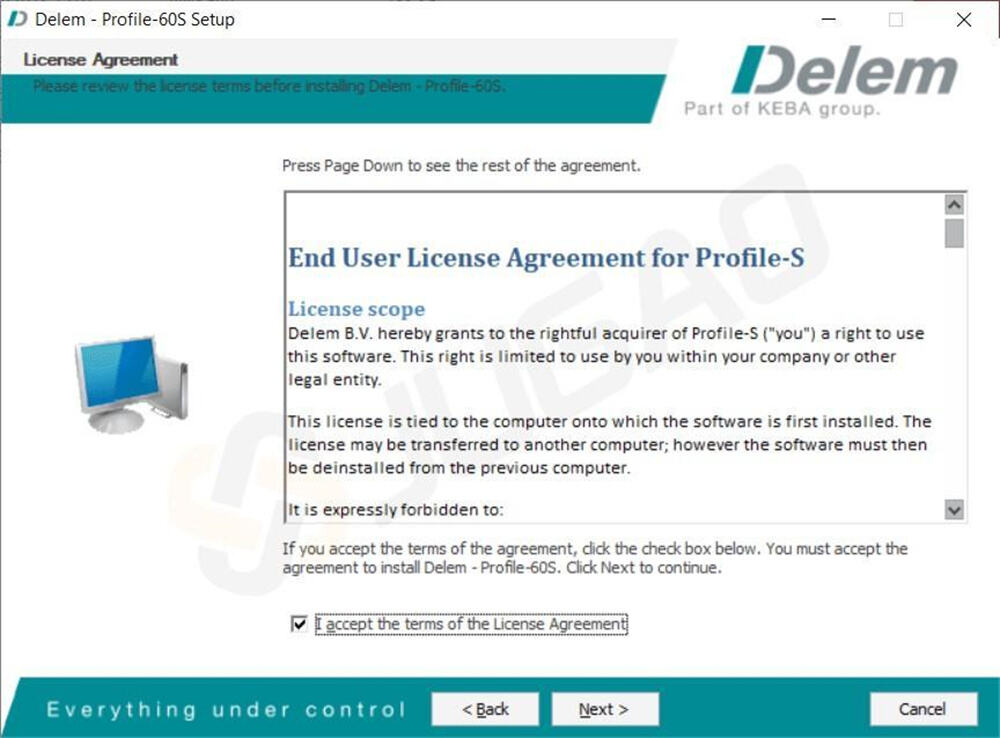

שלב 3: לקבל את הסכם הרישיון של התוכנה

התוכנה להתקנה תוביל לדף "הסכם רשיון תוכנה"; קרא את תנאי הסכם זהירות:

• אם אתה מסכים לתנאים, סמן את האפשרות "אני מקבל"... והחץ על "באחרונה" כדי להמשיך בהתקנה;

• אם אינך מסכים לתנאים, בחר "אני לא מקבל"...

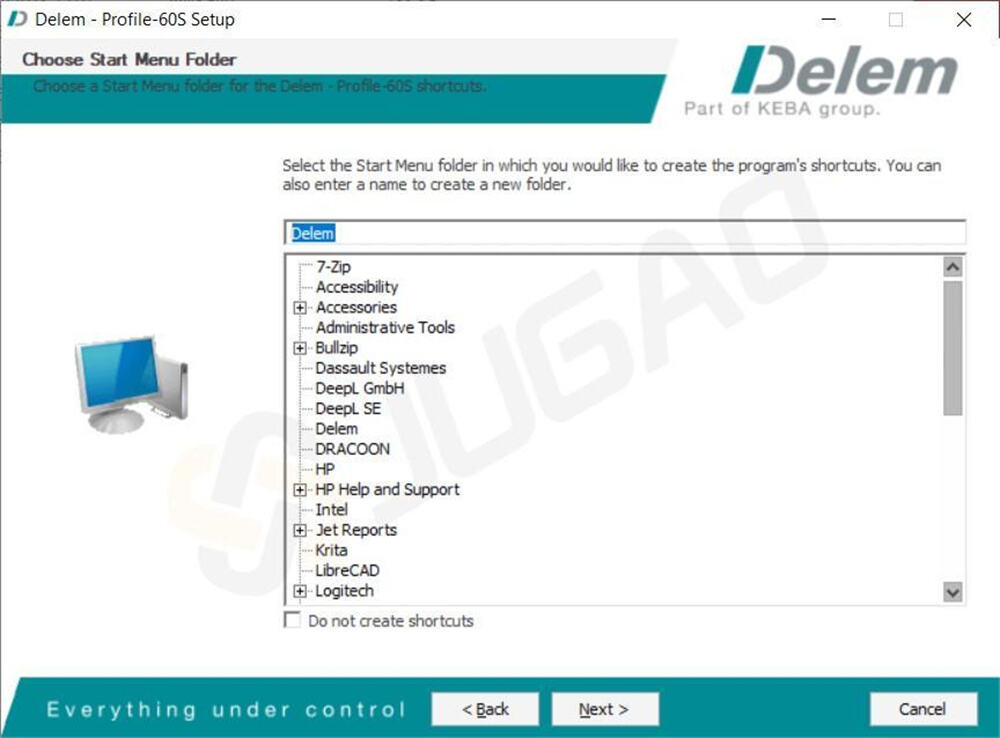

שלב 4: להגדיר הגדרות התקנה

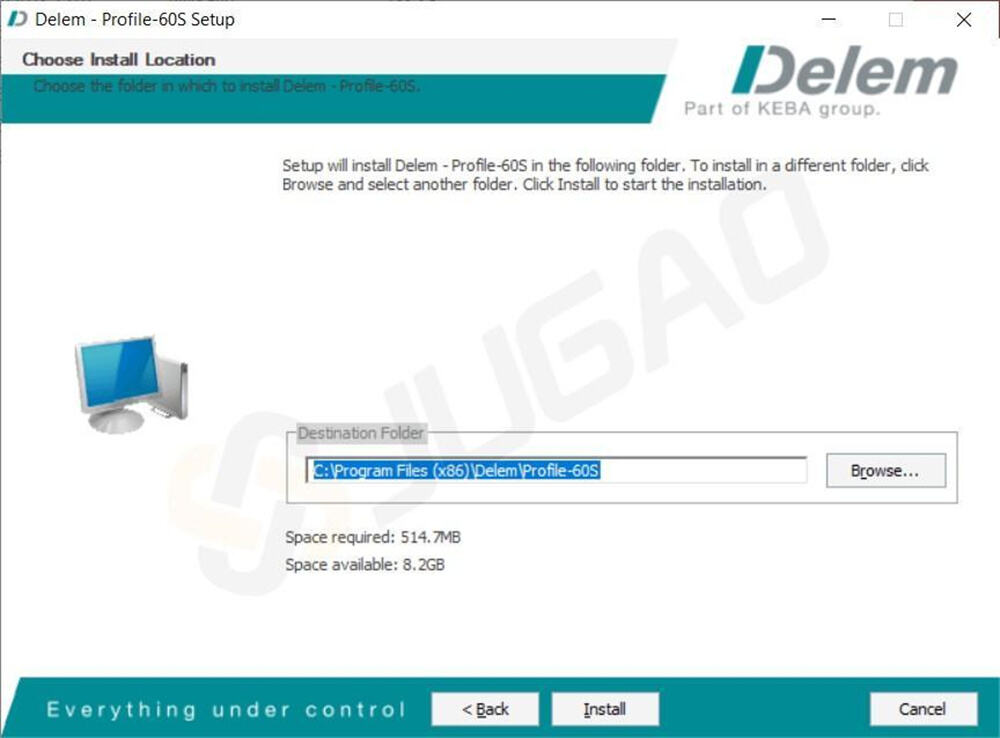

הגדיר את נתיב ההתקנה ואת שם התיקיה עבור התוכנה:

• נתיב ההתקנה המקובל הוא "C:\ Program Files (x86) \ Delem\ Profile-60S";

• כדי לשנות את הנתיב, לחץ על כפתור "העיין" כדי לבחור את התיקייה היעד. לאחר אישור הנתיב, לחץ על "הקנה" כדי להתחיל את תהליך העתק והקמת הקובץ.

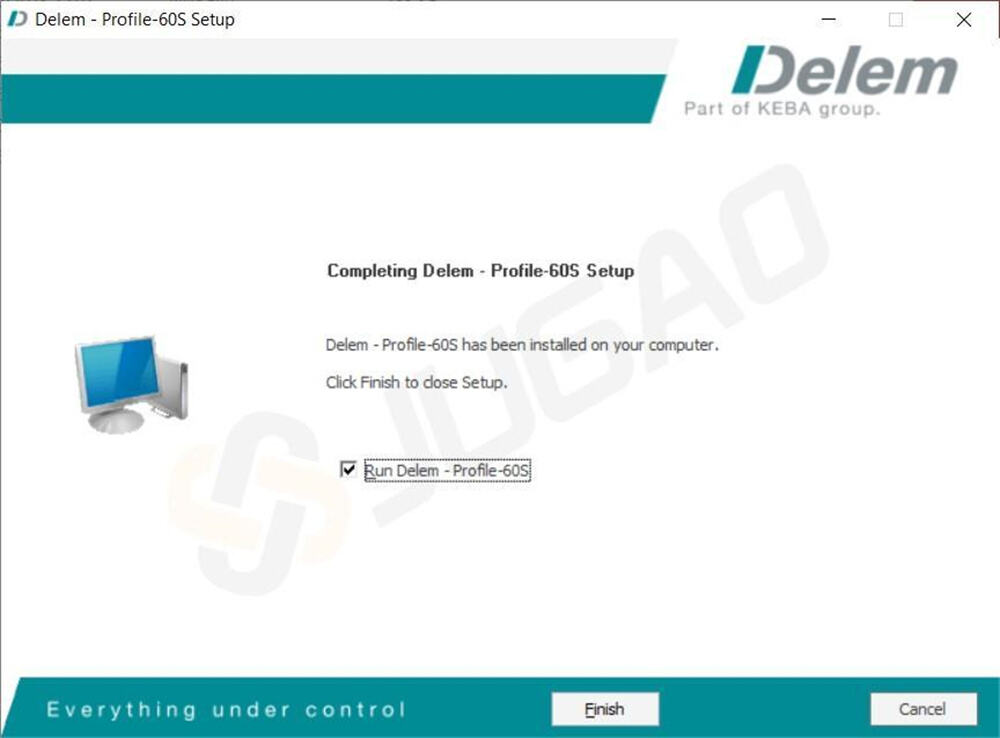

שלב 5: סיום ההתקנה

חכה לתוכנית ההתקנה להעתיק אוטומטית קבצים לתיקיית הדיסק הקשיח המפורט (אין צורך בפעולה ידנית במהלך התהליך). לאחר שהבר התקדמות הושלם, לחץ על "סיום" כדי לסיים את ההתקנה לא צריך להפעיל מחדש את המחשב, והמתוכנה יכולה לשמש כרגיל.

הערות לאחר ההתקנה

1. סמלי שולחן עבודה: לאחר ההתקנה כברירת מחדל, ייווצרו שני סמלים מרכזיים על שולחן העבודה:

"תוכנת Profile-60S": כניסה ישירה להפעלת התוכנה;

"מדריכי הפעלה של הבקר DA-60S": מדריך הפעלה של מערכת הבקר DA-60S.

1. רשומת תפריט התחלה: תיקייה חדשה בשם "Delem" תתווסף לתפריט התחלה של Windows (אם לא שונו הגדרות ההתקנה), הכוללת את "Profile-60S" (פריט הפעלת תוכנה) ואת "Profile-60S manuals" (אוסף מדריכי הפעלה).

2. דרישת מפתח רישוי (Dongle): לפני הפעלת התוכנה, יש לחבר את מפתח הרישוי USB — אם המפתח מחובר כראוי, התוכנה Profile-60S תיפתח אוטומטית; אם המפתח אינו מחובר או אינו פועל נכון, המערכת תציג הודעה על שגיאה. יש לבדוק את החיבור ולנסות שוב.

3. מדריך הפעלה ל-DELEM DA-66S Profile-60S

לאחר התקנת התוכנה, ניתן ליישם תכנות ובקרת מכונות כפיפה באמצעות מודולי הפונקציונליות הבאים. תהליכי הפעלה ופונקציות ליבה הם כדלקמן:

3.1 סקירה של זרימת העבודה Profile-60S

Profile-60S מאמץ עיצוב של "תהליך שטוח מלא", המכסה את מחזור החיים כולו של "קריאה למוצרים קיימים → יצור מוצרים חדשים → ייצור תוכניות → פלט נתונים" עם לוגיקת פעולה ברורה:

• הדרכת מצב: מקשי בחירת המodes בתחתית הממשק משמשים כמדריך פעולות מרכזי, כאשר כברירת מחדל מתחיל המצב "מוצרים" משמאל;

• תמיכה עזר: התוכנה כוללת פונקציות עזר בזמן אמת, והמדריך להפעלה מותקן בו זמנית עם התוכנה – ניתן להתייחס אליו בכל עת כדי לפתור שאלות תכנות;

• יתרונות מתקדמים: בהשוואה למערכת DA-60S הקודמת, Profile-60S מוסיף שלוש פונקציות עיקריות:

◦ כפתור "ספריית מכונה": שינוי ישיר של פרמטרי המכונה כדי להבטיח התאמה מלאה להגדרות בקר הפרס הידראולי;

◦ הדפסת מוצר: לחץ על "הדפס" במצב "מוצרים" כדי להפיק את הפרמטרים ונתוני התוכנית של המוצר שנבחר;

◦ העברה מרובה מסופים: במצב "העברה", ניתן להעביר נתוני מוצר ונתוני כלים לדיסק קשיח, התקן USB או מיקום אחסון רשת;

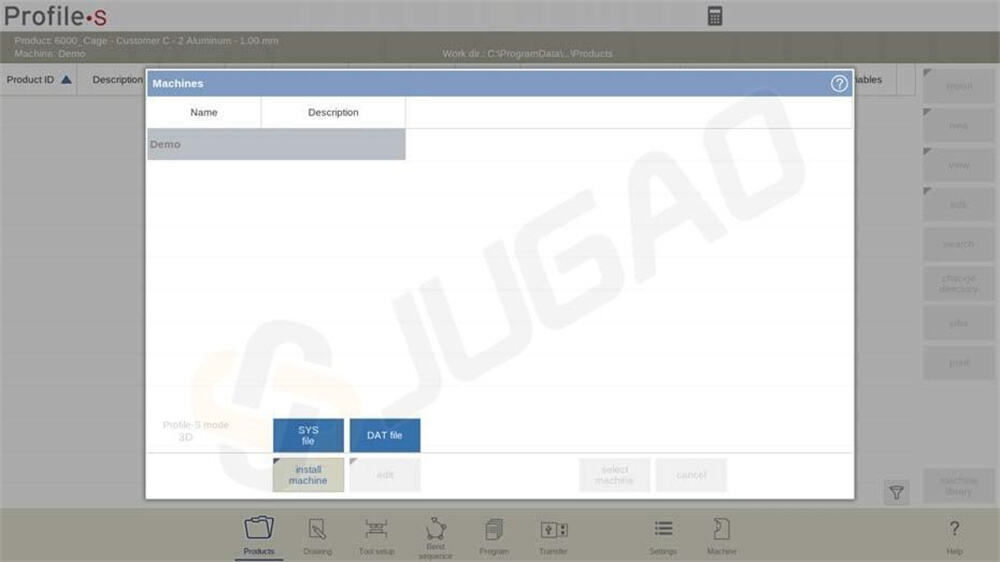

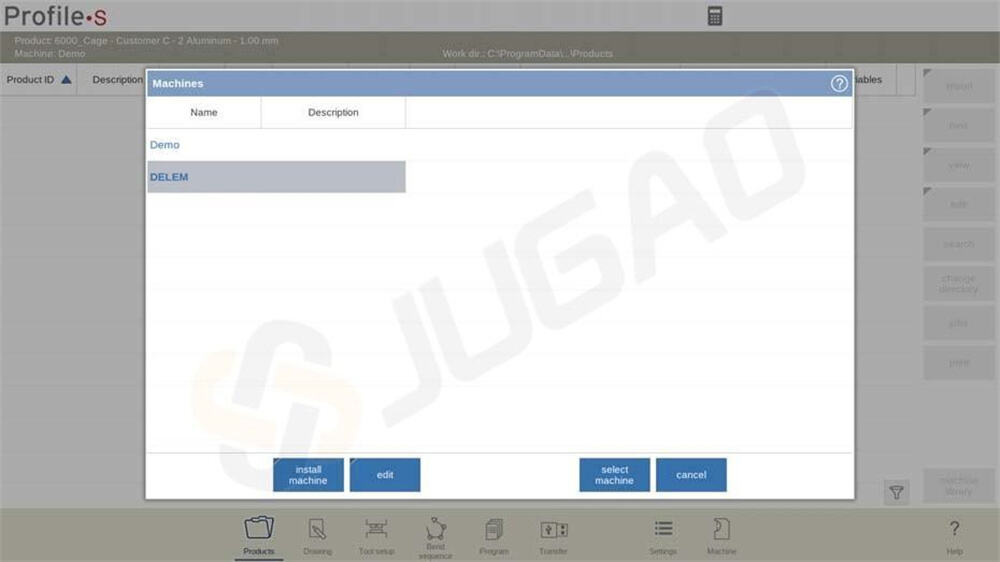

3.2 ניהול ספריית מכונות (הבטחת תאימות ציוד)

סנכרון פרמטרים בין ה-Profile-60S למכונות קיפול הוא חיוני לפעולת ציוד מתואמת. פונקציית "ספריית המכונה" מאפשרת "תחנת תכנות אחת להתאמה למספר מכשירים". הפעולות הספציפיות הן כדלקמן:

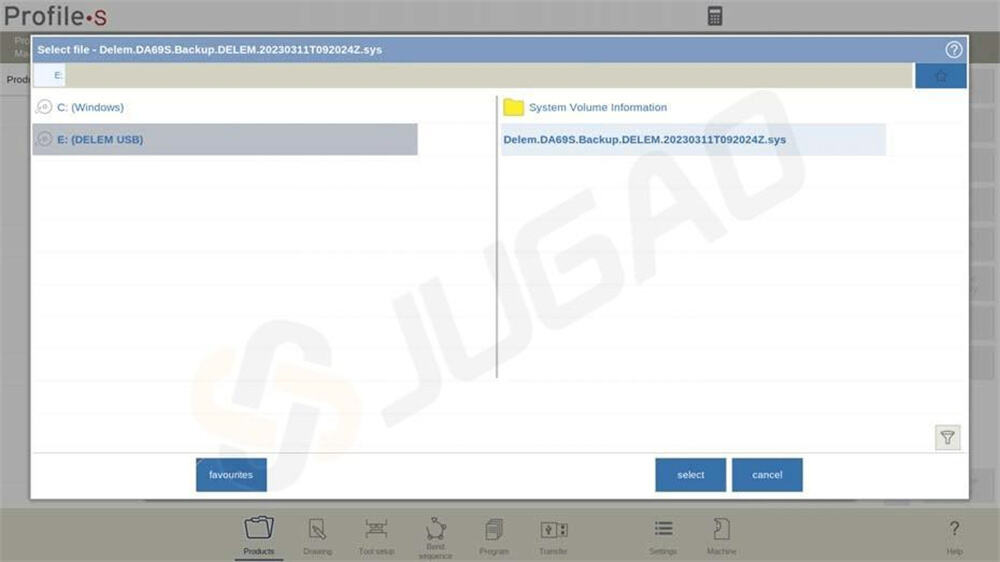

• הוספת מכונה: במצב "מוצרים", לחץ על "ספריית מכונה" ובחר ב"התקנת מכונה", ואז עקוב אחר ההנחיות כדי להשלים את הוספת המכשיר החדש;

• יצירת קובץ תצורת התקן: במצב "מכונה" של מערכת הבקרה DA-60S, בחרו באפשרות "גיבוי מערכת" — המערכת תיצור קובץ גיבוי בפורמט .dat של פרמטרי המכשיר. העתיקו קובץ זה לדרייב USB והעלו אותו ל-Profile-60S כדי להשלים את סנכרון פרמטרי המכשיר;

• ניהול מכשירים: שם המכונה המוצג ב-Profile-60S הוא זהה כברירת מחדל למערכת הבקרה המקורית. ניתן לעבור בין מכשירים באמצעות "בחירת מכונה" או לשנות את שם המכונה (ללא השפעה על הפרמטרים) באמצעות פונקציית "עריכה".

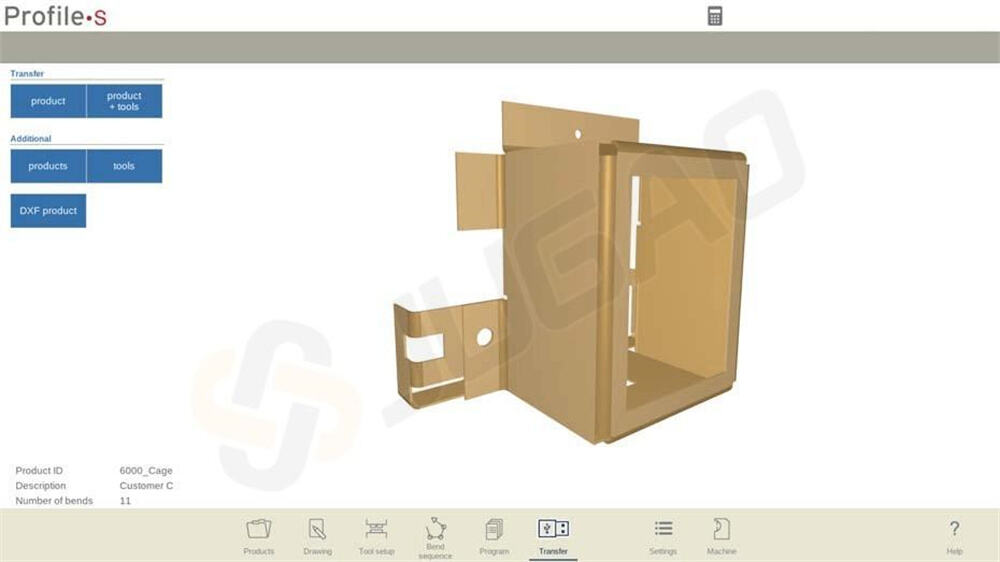

3.3 פונקציות הדפסה והעברה (פלט נתונים)

Profile-60S תומך בהדפסת נתונים והעברה למספר מסופים כדי לעמוד בצרכים בשיתוף ואחסון נתוני ייצור. שימו לב שאינן הפונקציות תומכות בגרסאות מסוימות בלבד:

(1) פונקציית הדפסה (תומכת רק בגרסאות Profile-S2D ו-Profile-S3D)

לחץ על כפתור "הדפסה" במצב "מוצרים" — המערכת תציג את תפריט ההדפסה הסטנדרטי של Windows. תוכל לבחור בחופשיות את המדפסת הרצויה, להגדיר גודל נייר, כמות עותקים וכו', ואז להפיק את מסמך נתוני המוצר.

(2) פונקציית העברה (נתמכת בכל הגרסאות)

לאחר השלמת עיצוב המוצר וייצור תוכנית CNC, המר את המצב ל"העברה" ובחר באחת משלוש שיטות ההעברה הבאות:

• מוצר: העברת רק נתוני התוכנית לתיקייה מסוימת (למשל, דיסק USB, כונן קשיח);

• מוצר + כלים: העברת נתוני התוכנית יחד עם נתוני הפרמטרים של הכלים בשימוש, כדי להבטיח שהמכשיר יקבל תצורה מלאה;

• מוצר DXF ( נתמך רק ב-Profile-S2D/S3D): ייצוא נתוני מוצר (כולל חיסורי קיפול) כ"גרפיקה של מתאר" בפורמט DXF לצורך שינויי עיצוב עתידיים או לארכיון.

bên cạnh המוצר/כלי הנבחר כרגע, תוכל גם להעביר בתצורה מקובצת נתונים של מוצרים או כלים אחרים כדי לשפר את היעילות.

3.4 שילובי מקשי קיצור (אופטימיזציה של חווית הפעלה)

Profile-60S תומך במקשי הקיצור הבאים כדי להתאים במהירות את מצב תצוגת הממשק:

• Alt + Enter: מעבר בין מצבי "תצוגה מלאה/תצוגה בתוך חלון";

• F11: הצגה או הסתרה של סרגל הכותרת וגבולות החלון של Windows (מתאים לسينריאוס הדורשים תצוגה רחבה יותר לפעילות);

4. שאלות נפוצות (FAQ)

1. אילו פונקציות ספציפיות מציע DELEM DA-66S Profile-60S?

הפונקציות הליבה של המערכת מתוכננות סביב פעולת "דיוק גבוה ויעילות" של מכונות כרסום, הכוללות:

• תכנות גרפי דו-ממדי: מפשט את תהליך התכנות באמצעות ממשק גרפי אינטואיטיבי ומפחית את סף הכניסה להפעלה;

• חישוב אוטומטי של סדר קיפול: המערכת מתכננת באופן אוטומטי את סדר הקיפול האופטימלי על סמך פרמטרים של המוצר, כדי להפחית שגיאות הנגרמות עקב התערבות ידנית;

• עיבוד נתונים בזמן אמת: ניטור דינמי של שינויי פרמטרים במהלך תהליך הכיפוף, כדי להבטיח דיוק ויציבות בתפעול הציוד.

2. האם מערכת זו תואמת לכל סוגי מכונות הכיפוף?

Profile-60S תואם לרוב מכונות הכיפוף המרכזיות בשוק. עם זאת, בשל הבדלים בין מודלי ציוד ותצורות חומרה של יצרנים שונים, מומלץ ליצור קשר עם יצרן הציוד לפני הקנייה או ההתקנה, כדי לאשר את התאימותו למודל מכונת הכיפוף הספציפית שלכם ולמנוע בעיות תפעול הנובעות ממיסוי פרמטרים.

3. האם ניתן לשדרוג המערכת עם מערכות CNC קיימות?

כן. פרופיל-60S תומך בדרך כלל באינטגרציה עם מערכות CNC קיימות. לאחר האינטגרציה, ניתן להשיג "תקשורת נתונים ושליטה שיתופית" כדי לדייק עוד יותר את תהליך הייצור. עם זאת, יש לאשר עם ספק המערכת את פתרונות האינטגרציה הספציפיים (כגון התאמת ממשק, פרוטוקולי החלפת נתונים וכו') כדי להבטיח תאימות עם התצורה הקיימת של קו הייצור שלך.

5. -לא. מסקנה

ה-DELEM DA-66S Profile-60S הוא רכיב מרכזי בקרת CNC של מכונות כרסום. הפונקציות שלו כוללות את כל התהליך של "הגדרת פרמטרים → תכנות → פלט נתונים → שיתוף פעולה בין ציוד", ובכך ממלא תפקיד חשוב בשיפור הדיוק והיעילות בעיבוד מתכות. שליטה בתהליך ההתקנה ובלוגיקה המבצעית מאפשרת לשחרר את הפוטנציאל המלא של מכונות הכרסום ולממש שדרוג אוטומציה של קו הייצור.

אם אתם צריכים תמיכה נוספת במהלך שדרוג ציוד או הפעלת תוכנה, ניתן ליצור קשר עם צוות הטכני לשם סיוע, או לקבל הדרכה מפורטת יותר באמצעות הדרכה להפעלה המותקנת יחד עם התוכנה, על מנת לסייע באופטימיזציה של מערכת האוטומציה התעשייתית שלכם.