Faktor yang Menentukan Radius Bending pada Logam Lembaran: Panduan Teknis yang Komprehensif

Radius tekukan adalah parameter kritis dalam fabrikasi logam lembaran, yang mempengaruhi kekuatan bagian, penampilan, dan kemampuan produksi. Memilih radius tekukan yang sesuai memastikan integritas struktural sekaligus menghindari cacat seperti retakan atau deformasi. Dokumen ini membahas faktor-faktor utama yang mempengaruhi radius tekukan pada logam lembaran serta memberikan praktik terbaik untuk operasi penekukan yang optimal.

Definisi jari-jari bejat

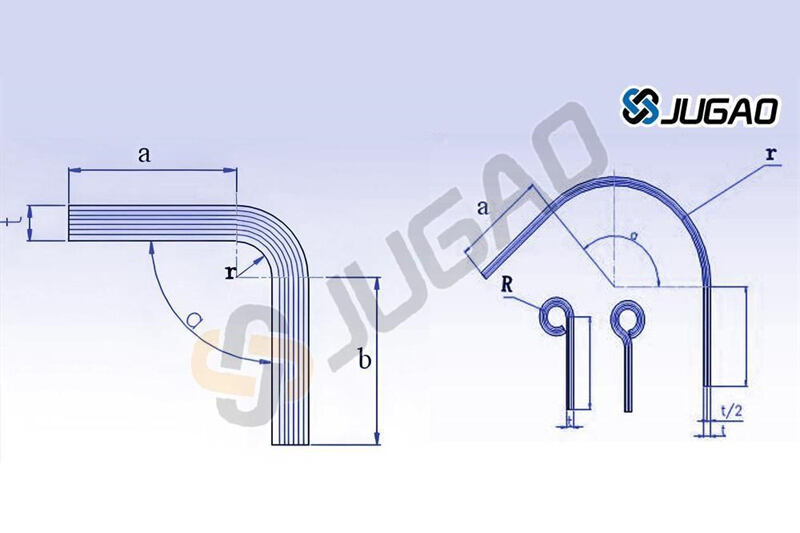

Radius tekukan mengacu pada radius dalam dari bagian logam lembaran yang ditekuk. Radius ini diukur dari kurvatur dalam tekukan ke garis tengah ketebalan material.

Tekukan Tajam (Radius Kecil): Radius mendekati nol, biasanya memerlukan perkakas khusus.

Tekukan Standar (Radius Sedang): Umum digunakan pada sebagian besar aplikasi.

Bengkok Radius Besar: Digunakan untuk tujuan estetika atau struktural.

Faktor Utama yang Mempengaruhi Radius Bengkok

1. sifat material

a) Jenis Material

Logam yang berbeda memiliki sifat ductility dan elongasi yang berbeda:

Aluminium: Lebih ductile, memungkinkan bengkokan yang lebih ketat.

Baja Tahan Karat: Lebih keras, membutuhkan radius bengkok yang lebih besar untuk mencegah retakan.

Baja Karbon Rendah: Kemampuan bengkok sedang, umum digunakan dalam aplikasi standar.

Tembaga & Kuningan: Sangat ductile, cocok untuk radius yang ketat.

b) Ketebalan Material (T)

Aturan Umum: Radius bengkok minimum ≈ 1×T (untuk material lunak) hingga 2×T (untuk material keras).

Contoh:

aluminium 2mm → Radius minimum = 2mm (1×T).

baja tahan karat 2mm → Radius minimum = 4mm (2×T).

c) Arah Butir (Anisotropi)

Membengkokkan sejajar dengan arah butir meningkatkan risiko retakan.

Membengkokkan tegak lurus terhadap arah butir memungkinkan radius yang lebih kecil.

2. Kemampuan Alat & Mesin

a) Pemilihan Punch & Die

Bukaan V-die yang lebih kecil memungkinkan pembengkokan yang lebih tajam tetapi meningkatkan tonase yang dibutuhkan.

Die yang lebih besar menghasilkan radius yang lebih besar tetapi mengurangi tegangan pada material.

b) Tonnage Mesin Press Brake

Mesin dengan tonase lebih tinggi dapat mencapai lipatan yang lebih ketat pada material yang lebih tebal.

Tonase yang tidak mencukupi menyebabkan lipatan tidak sempurna atau efek pegas (springback).

c) Material & Keausan Alat

Matriks (dies) yang aus atau terkelupas meningkatkan risiko cacat permukaan.

Alat dari baja yang dikeraskan mempertahankan ketelitian dalam penggunaan jangka panjang.

3. Metode Pembentukan

Lipatan Udara (Air Bending): Menggunakan radius punch yang lebih kecil, menghasilkan radius alami berdasarkan elastisitas material.

Bottoming / Coining: Memaksa material masuk ke dalam matriks, menciptakan radius yang lebih presisi tetapi memerlukan tonase lebih tinggi.

Lipatan Gulung (Roll Bending): Digunakan untuk kurva beradius besar (misalnya, silinder).

4. Sudut Lipatan & Efek Pegas (Springback)

Bengkokan yang lebih ketat (sudut lancip) memerlukan radius yang lebih kecil tetapi dapat meningkatkan springback.

Kompensasi springback harus dipertimbangkan dalam pemrograman CNC.

5. Pertimbangan Finishing Permukaan & Lapisan

Lembaran yang dicat atau dilapisi dapat retak jika dibengkokkan terlalu tajam.

Pengobatan sebelum pembengkokkan (misalnya, annealing) dapat meningkatkan kemampuan bentuk.

Menghitung Radius Bengkok Minimum

1. Rumus Empiris

Radius bengkok minimum (R_min) dapat diperkirakan sebagai: Rmin=K×T

Dimana:

K = Faktor material (0,5 untuk aluminium lunak, 2 untuk baja tahan karat).

T = Ketebalan material.

2. Standar Industri (Contoh Pedoman)

| Bahan | Jari-jari Bending Minimum yang Direkomendasikan |

| Aluminium Lembut | 0,5× T |

| BajaRingan | 1× T |

| Baja tahan karat | 2× T |

| Tembaga | 0,8× T |

Cacat Umum Akibat Jari-jari Bending yang Tidak Benar

Retak (Sisi Luar Bending): Disebabkan oleh penipisan berlebihan.

Berkerut (Sisi Dalam Bending): Akibat jari-jari terlalu besar pada lembaran tipis.

Springback: Material sedikit kembali setelah dibentuk, mempengaruhi akurasi.

Goresan Permukaan: Disebabkan oleh pemilihan die yang tidak tepat atau pelumasan yang kurang memadai.

Praktik Terbaik untuk Pemilihan Radius Bending yang Optimal

Konsultasikan Lembar Data Material untuk nilai elongasi dan faktor-K.

Gunakan Peralatan yang Tepat (lebar V-die dan radius punch yang benar).

Lakukan Uji Bending sebelum produksi penuh.

Berikan Pelumasan untuk mengurangi gesekan dan retakan.

Pertimbangkan Perlakuan Setelah Bending (relaksasi tegangan, penghilangan duri).

Kesimpulan

Radius bending pada logam lembaran ditentukan oleh sifat material, ketebalan, peralatan, dan metode bending. Pemilihan yang tepat menjamin integritas struktural, meminimalkan cacat, serta meningkatkan kemampuan produksi. Dengan mengikuti panduan industri dan melakukan uji bending, produsen dapat mengoptimalkan proses bending untuk hasil berkualitas tinggi.