Մետաղի ծռման գործընթացների տեսակներ

Թերթային մետաղի ծռման տեխնիկաները ունեն ընդհանուր նպատակ՝ մետաղը ձևավորելու ցանկալի ձևերով, սակայն նրանց գործառույթների սկզբունքները կարող են զգալիորեն տարբերվել: Այս մեթոդների տիրապետումը պահանջում է հիմնարար գործոնների հասկացողություն, ինչպիսիք են նյութի հաստությունը, ծլի չափերը, կորության շառավիղը և նախատեսված կիրառությունը՝ այն բոլորը, որոնք ազդում են ամենահարմար ծռման գործընթացի ընտրության վրա:

Ստորև ներկայացված մեթոդները ցույց են տալիս ոչ միայն թե ինչպես ծլել թերթային մետաղը, այլ նաև թե ինչպես ընտրել ճիշտ տեխնիկան՝ օպտիմալ արդյունքներ ստանալու համար: Թերթային մետաղի ամենատարածված ծռման մեթոդներն են.

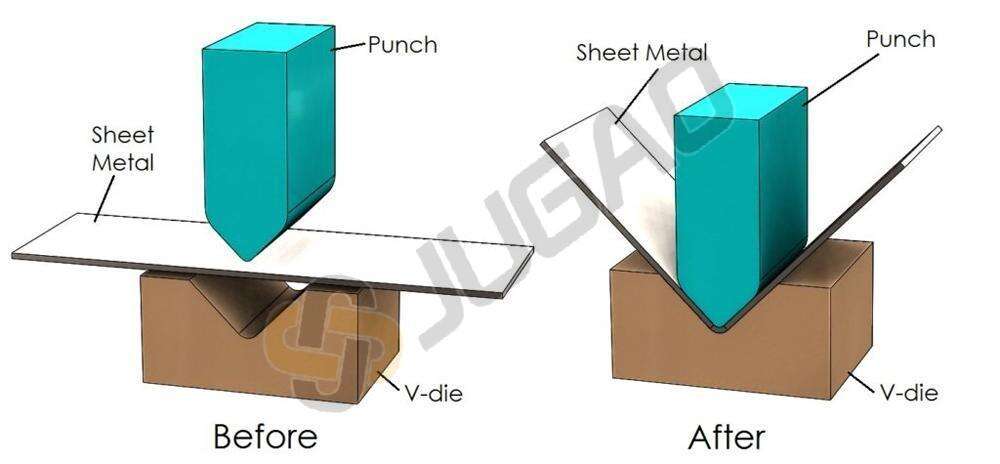

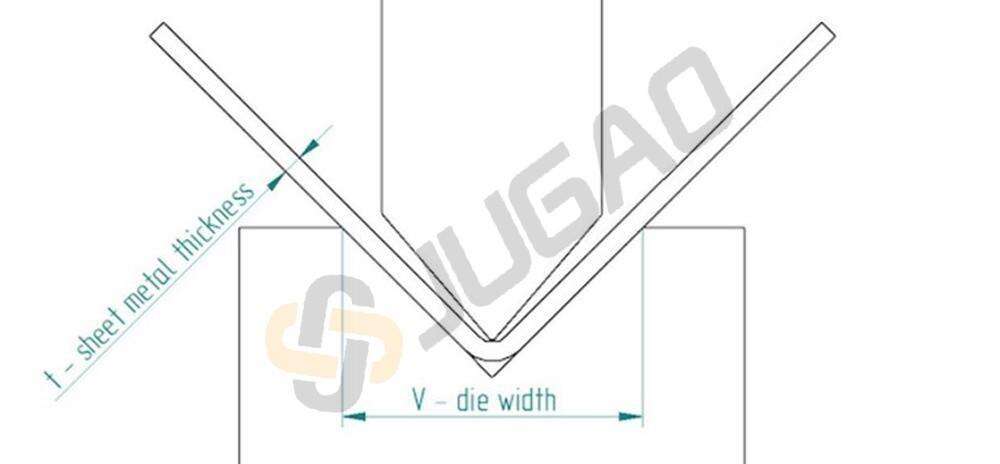

V-ձև փոխանցմամբ ծռում

Սա հորիզոնական ծռման ամենատարածված մեթոդն է, որը կիրառելի է ծռման մեծամասնության նախագծերի համար: Այն օգտագործում է փոխարկիչ և V-ձև փոկ, որպեսզի ստանա սալիկի ցանկալի անկյունը: Գործընթացի ընթացքում փոխարկիչը սեղմում է մետաղական սալը V-ձև փոկի մեջ:

Ծռման արդյունքում ստացված անկյունը կախված է այն խորությունից, որին փոխարկիչը մտնում է փոկի մեջ: Այս մեթոդը պարզ է և արդյունավետ, քանի որ հաճախ թույլ է տալիս մանրամասը կրկին դիրք չփոխելով ծռել:

V-ձև փոկով ծռումը կարող է բաժանվել երեք ենթատեսակների.

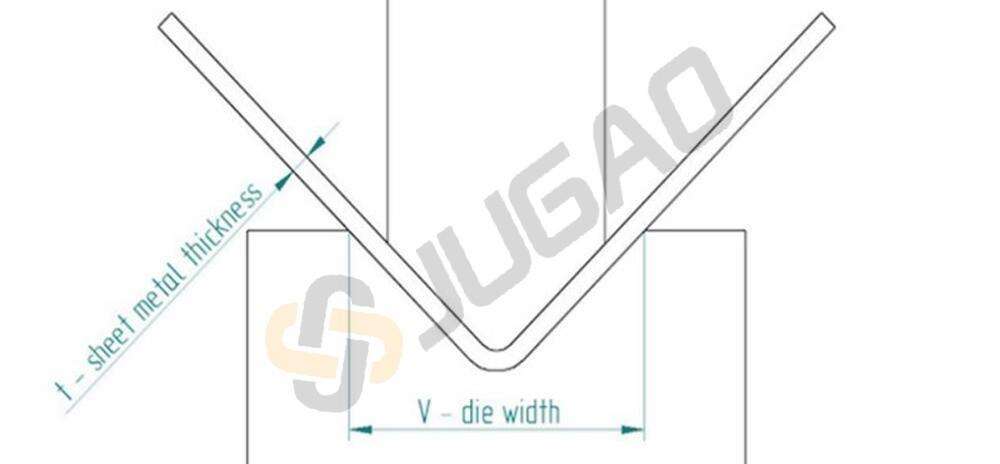

Հատակի տեղադրում

Երկնային ծռումը նման է օդային ծռմանը, սակայն հիմնական տարբերությամբ. փոխարկիչը ստիպում է սալը ամբողջությամբ մտնել փոկի մեջ, մինչև այն լրիվ շփվի փոկի մակերևույթների հետ: Այս մոտեցումը նվազեցնում է օդային ծռման հետ կապված թերությունների ռիսկը:

Այս մեթոդը պահանջում է ավելի բարձր տոնաժ, քանի որ ձևավորման ավարտին ավելի շատ ուժ է անհրաժեշտ դեֆորմացիան ավարտելու և մասը տեղում պահելու համար: Այն համատեղելի է տարբեր V-ձև փոկերի կոնֆիգուրացիաների հետ:

Հատվածը բարձր ճշգրտություն է ապահովում և չի պահանջում ճշգրիտ տոննաժի կառավարում, ինչը դարձնում է այն հարմար հին կամ պակաս ճշգրիտ պրես-թռույգների համար:

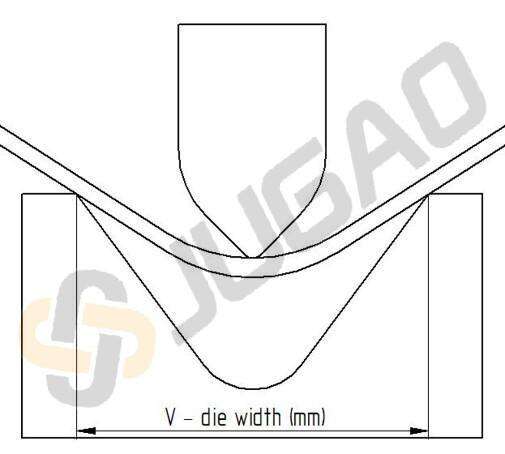

Մետաղադրամի ձևավորում

Մետաղադրամի ձևավորումը ներառում է մետաղական թիթեղի սեղմումը փոխանցիչի և փոկի միջև՝ շատ բարձր տոննաժի տակ: Սա արդյունքում տալիս է բարձր ճշգրտությամբ ծռման անկյուն՝ նվազագույն սրինգի ազդեցությամբ:

Չնայած մետաղադրամի ձևավորումը ապահովում է հիանալի ճշգրտություն, սակայն այն պահանջում է բարձր տոննաժ և ունի ավելի երկար ցիկլի տևողություն՝ համեմատած այլ մեթոդների հետ:

Օդային թեքում

Օդային ծռումը (կամ մասնակի ծռումը) պակաս ճշգրիտ է, քան հատումը կամ մետաղադրամի ձևավորումը, սակայն լայնորեն օգտագործվում է իր պարզության և գործիքավորման ճկունության շնորհիվ, քանի որ հատուկ փոկեր չեն պահանջվում:

Նշանակալի թերություն է հանդիսանում այն, որ օդային ծռումը ավելի խոցելի է սրինգի ազդեցության նկատմամբ:

Այս գործընթացում փոխանցիչը թիթեղի վրա փոկի բացվածքից վերև երկու կետերում է կիրառում ուժ: Քանի որ թիթեղը չի շփվում փոկի հատակի հետ, սովորաբար V-ձև փոկով օդային ծռման համար օգտագործվում է պրես-թռույգ:

(Ճնշման ճկոցը թերթային մետաղի մշակման մեջ օգտագործվող սարք է, որն ամրացնում է մշակվող մանրակը և կիրառում է ուժ՝ փոխադրելով այն փոխադրիչի և փոկի միջև՝ ստանալու համար ցանկալի ճկվածքը):

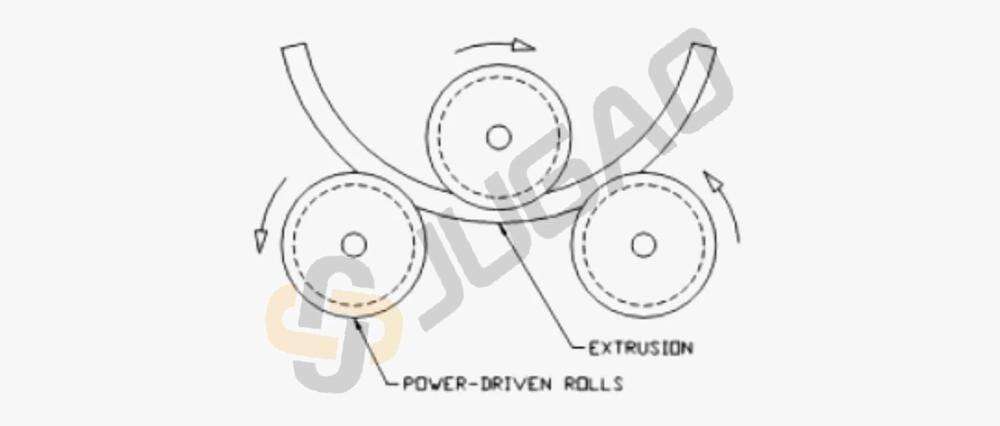

Ռոլիկներով ծռում

Ռոլիկներով ծռումը օգտագործում է 2, 3 կամ 4 ռոլիկների համակարգ՝ մետաղական թերթերը կորացված ձևեր ստանալու համար: Ամենատարածված կառուցվածքը 3 ռոլիկի պիրամիդային կազմավորումն է, որտեղ վերին ռոլիկը կարգավորվող է, իսկ ստորին երկուսը՝ ֆիքսված:

Թերթը տրվում է վերին ռոլիկի և երկու ֆիքսված ռոլիկների միջև: Երբ ռոլիկները պտտվում են, նրանք բռնում են թերթը, մինչդեռ կարգավորվող ռոլիկը կիրառում է ներքևի ճնշում՝ հասնելու ցանկալի կորությանը: 4 ռոլիկով համակարգը ներառում է լրացուցիչ ռոլիկ՝ ավելի լավ աջակցություն ապահովելու համար, ինչը այն դարձնում է իդեալական ծանր կիրառումների համար:

Այս մեթոդը հիմնականում օգտագործվում է գլանաձև կամ կոնաձև ձևեր ստանալու համար, ինչպիսիք են խողովակները, գազային բալոնները, տանկերը, ճնշման տարաները և խողովակները:

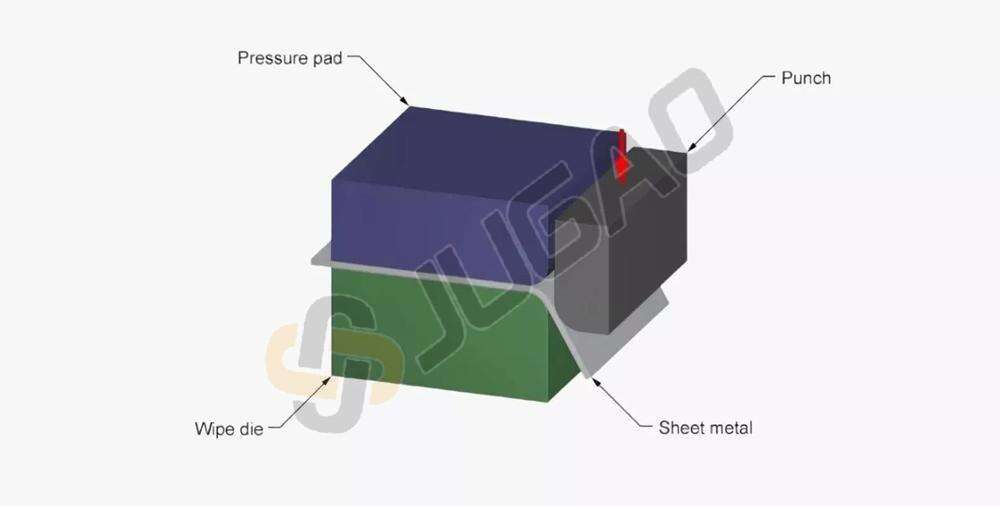

Սղոցային ծռում

Թեքումը սրբիչով (կամ եզրի թեքում) օգտագործում է սրբիչ փոկ, և խոցանակ: Լայնատախտակը ամրացվում է փոկի և ճնշման սալի միջև, որտեղ եզրագծվում է թեքման ենթակա հատվածը: Այնուհետև խոցանակը շարժվում է ներքև, սրբում նյութը փոկի եզրի վրա՝ ձևավորելով ցանկալի անկյունը: Այս մեթոդը փոքր եզրերի համար ճնշակային թեքման լավ այլընտրանք է:

Այս տեխնիկան թույլ է տալիս միաժամանակ ձևավորել բազմաթիվ եզրեր, ինչը բարձրացնում է արտադրողականությունը: Այն նաև նվազագույնի է հասցնում թեքման գոտում մակերեսային ճեղքերի առաջացման ռիսկը:

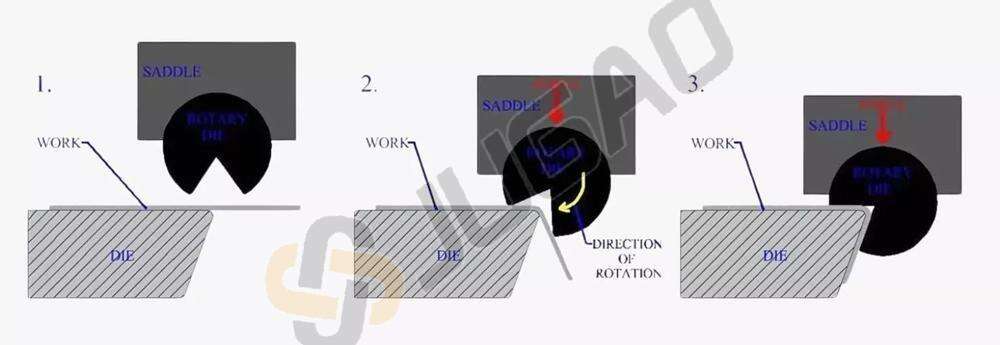

Ռոտացիոն թեքում

Պտտացող ծնկահանը հաճախ օգտագործվում է խողովակներ և փակուղիներ ծնկահանելու համար՝ 1°-ից մինչև 180° կորությամբ, սակայն կիրառելի է նաև թերթային մետաղի դեպքում: Գործընթացը ներառում է երեք հիմնական բաղադրիչ՝ ծնկահանող ձև, ամրակալման ձև և ճնշման ձև: Ծնկահանող և ամրակալման ձևերը ամրացնում են մշակվող մասը, իսկ ճնշման ձևը կիրառում է շոշափողային ուժ ազատ ծայրից դեպի ծնկահանման հաշվարկային կետը: Պտտվող ձևերը կարող են կարգավորվել՝ ճշգրիտ կեղծման անկյուն և շառավիղ ապահովելու համար: Խողովակները ծնկահանելիս հաճախ ներսում տեղադրվում է մանդրել՝ փլուզումը կանխելու համար, սակայն պինդ թերթային մետաղական մասերի համար դա անհրաժեշտ չէ:

Այս ձևավորման մեթոդը հարմար է հարթ թերթերում ծնկահանումներ ստեղծելու համար և լայնորեն օգտագործվում է խողովակների և փակուղիների արտադրության մեջ:

Պտտացող ծնկահանումը ապահովում է հիանալի վերահսկողություն՝ թույլ տալով ±0.5° ճշգրտությամբ լարված հանգույցներ: Քանի որ անհրաժեշտ տոնաժը 50%-ից 80% ցածր է մյուս մեթոդների համեմատ, մակերեսի սխալների, ինչպիսիք են ճեղքերը, առաջացման ռիսկը զգալիորեն նվազում է: