Ինչպե՞ս է լազերային կտրումը օգուտ բերում նոր էներգետիկայի ոլորտում

Լազերային կտրումը դարձել է նոր էներգետիկայի արտադրության արդյունաբերության հիմնական գործընթաց, որը բարձրացնում է արտադրության արագությունը, նյութերի օգտագործման արդյունավետությունը և մշակման ճշգրտությունը: Վերականգնվող էներգիայի շուկայի արագ ընդլայնման հետ մեկտեղ այս առաջադեմ մշակման տեխնոլոգիան ապահովում է նշանակալի մրցակցային առավելություններ այնպիսի ոլորտների համար, ինչպիսիք են արեւային էներգիան, մատակարարման արտադրությունը, քամու էներգիան և ջրածնային էներգիայի համակարգերը: Հետագա հոդվածներում ես մանրամասն կքննարկեմ, թե ինչպես է լազերային կտրումը նպաստում ժամանակակից էներգետիկայի արտադրության զարգացմանը, և կբացատրեմ, թե ինչպես կարող է ձեր ընկերությունը օգտվել այս տեխնոլոգիական առավելություններից՝ արդյունաբերության մեջ պահպանելով իր առաջատար դիրքը:

Լազերային կտրման դերը նոր էներգետիկայի ոլորտում

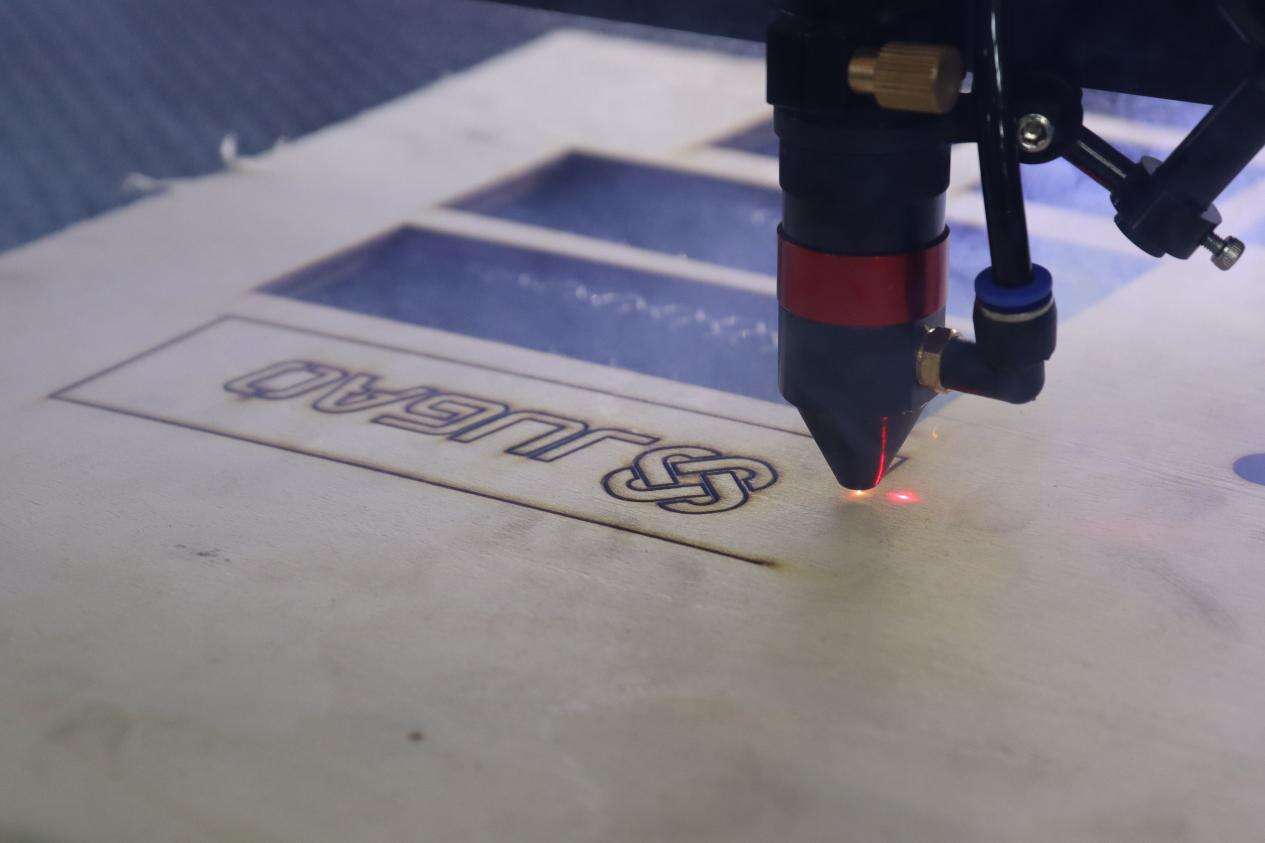

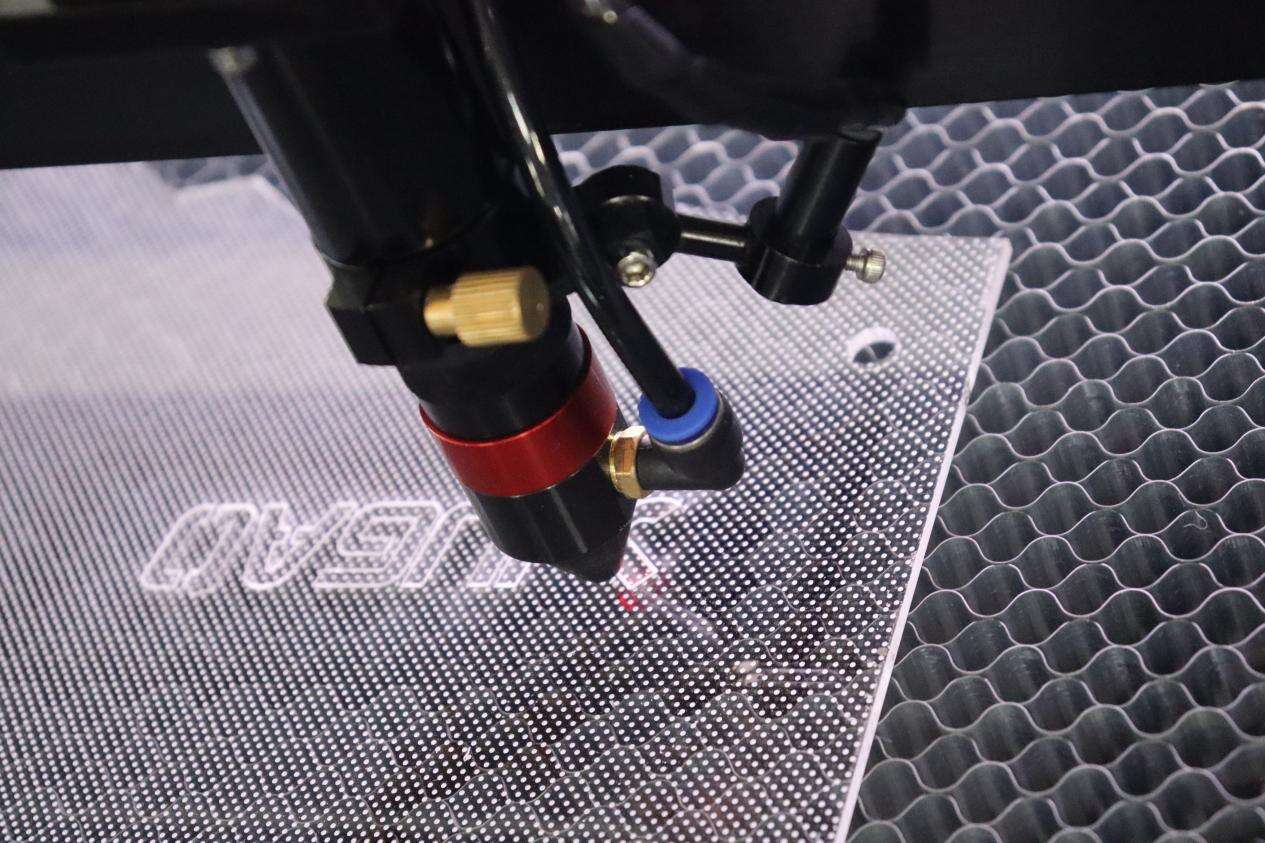

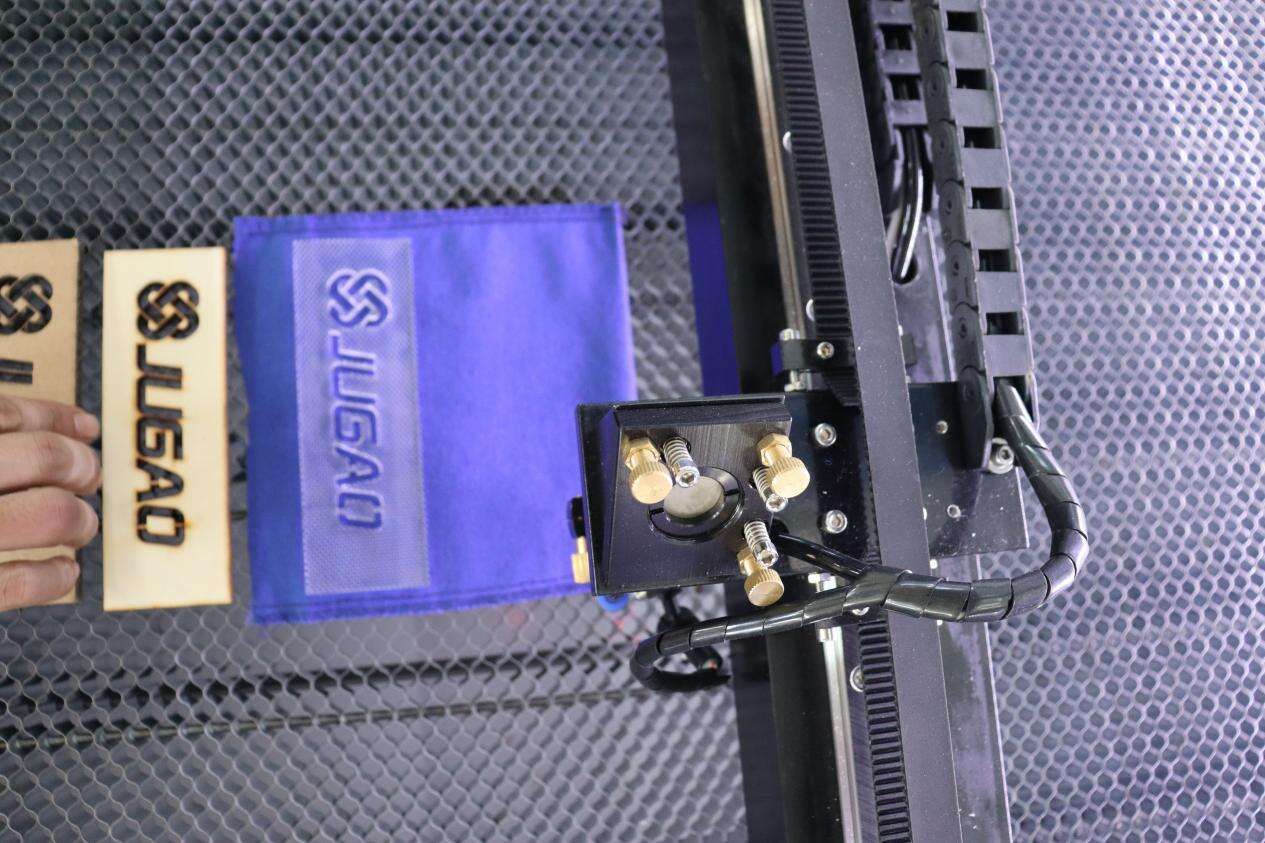

Նոր էներգետիկայի սարքավորումների արտադրության ոլորտում լազերային կտրումը խիտ, ճշգրիտ և կրկնվող հատկանիշների շնորհիվ օպտիմալ ընտրություն է ստացվում ստաինլես պողպատի, ալյումինի և պղնձի նման նյութերի մշակման համար: Այս հատկանիշները կարևոր են կանաչ էներգետիկայի համակարգերի կատարողականության և որակի ապահովման համար:

Ինչո՞ւ լազերային կտրումն օգտագործել արեւային վահանակների արտադրության համար

Շրջանակների և ամրակների արագ արտադրություն

Բարձր արագությամբ մանրաթելային լազերային կտրող տեխնոլոգիան զգալիորեն արագացրել է արևային սարքերի շրջանակների և պահակների արտադրությունը: Այս տեխնոլոգիան հնարավորություն է տալիս ալյումինե կամ ցինկապատ պողպատե թերթերը հատել արդյունավետ, մեծ ծավալով և բարձր ճշգրտությամբ՝ ապահովելով համապատասխան արդյունքներ, միաժամանակ արդյունավետ կրճատելով մարդու սխալները և զգալիորեն ավելացնելով արտադրական հզորությունը:

Բարակ նյութերի կտրման ճշգրտություն

Լազերային կտրումը հիանալի լուծում է արևային մասերի՝ արևային մարտկոցների շատ բարակ, թեթև և բարդ մասերի և դրանց բարձր ճշգրտության արտադրության պահանջների համար: Այս տեխնոլոգիան ապահովում է շատ փոքր թույլատրելի շեղումներ և մաքուր եզրեր, միաժամանակ արդյունավետ կերպով նվազեցնելով ջերմային դեֆորմացիան և նյութի լարվածությունը, որոնք առաջանում են ավանդական կտրման մեթոդների դեպքում: Սա ապահովում է, որ ներգործության ընթացքում զգայուն նյութերը չվնասվեն, ինչը հանգեցնում է ճշգրիտ արդյունքների:

Ինչպես է լազերային կտրումը բարելավում մարտկոցների և էլեկտրական տրանսպորտի մասերի արտադրությունը

Մարտկոցների կողպածների ճշգրիտ կտրում

Չափագրական ճշգրտությունը կարևոր է էլեկտրական տրանսպորտի և էներգիայի պահեստավորման համակարգերի համար նախատեսված մարտկոցների արտադրության ընթացքում: Լազերային կտրման տեխնոլոգիան հատկապես լավ է համապատասխանում ներկայացված բաղադրիչների ճշգրիտ արտադրությանը՝ խիստ ապահովելով չափերը ստանդարտ պողպատի և ալյումինի դեպքում, ապահովելով հիմնարար բաղադրիչների համար, ինչպիսիք են մարտկոցների կողպածները, ծածկույթները և միջանդամները:

Պղնձի և ալյումինի հետ համատեղելիություն

Այս երկու մետաղները էլեկտրական տրանսպորտի շարժիչների համար հիմնարար նշանակություն ունեցող նյութեր են, սակայն ավանդական կտրող մեթոդները անարդյունավետ են: Լազերային կտրումը ապահովում է մաքուր, օքսիդներից ազատ եզրեր, որը երաշխավորում է գերազանց էլեկտրահաղորդականություն:

Լազերային կտրման երկարաժամկետ առավելությունները նոր էներգետիկայի ոլորտում

Պակաս թափոն. Լազերային կտրումը նվազեցնում է նյութի կորուստը՝ իր ճշգրտության շնորհիվ:

Նվազած աշխատավարձի ծախսեր. Ավտոմատացված համակարգերը նվազեցնում են ձեռքով կատարվող գործողությունները:

Միատեղ որակ. Բարձր կարողություն ունեցող էներգետիկական արտադրանքների համար բանից է:

Շարժառություն. Հեշտությամբ փոխարկվում են մասերի և նյութերի տեսակները: