Plekkdetaili painderaadiust määravad tegurid: põhjalik tehniline juhend

Painderaadius on oluline parameeter lehtmetalli valmistamisel, see mõjutab osa tugevust, välimust ja valmistatavust. Õige painderaadiuse valik tagab struktuuriterviklikkuse ja vähendab vigastuste, nagu pragude või deformatsiooni, tekkimist. Käesolev dokument käsitleb lehtmetalli painderaadiust mõjutavaid tegureid ning pakub parimaid tavasid optimaalsete paindetööde jaoks.

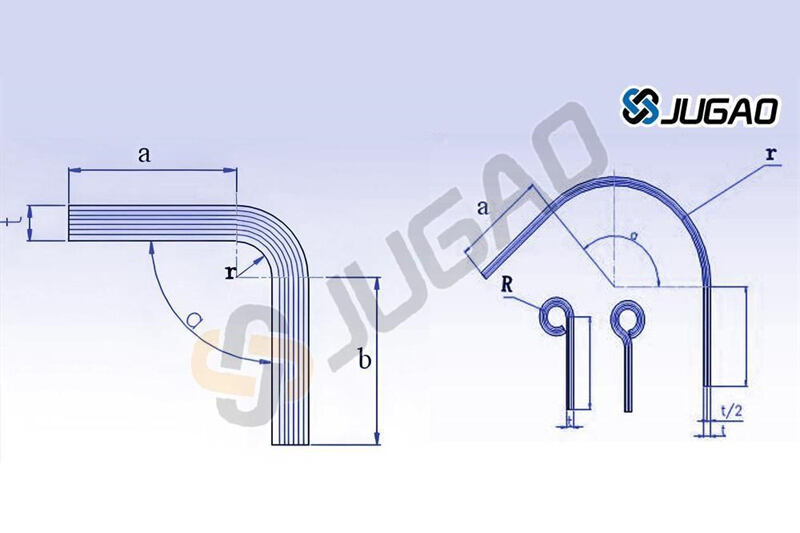

Painderaadiuse definitsioon

Painderaadius viitab painduva lehtmetalliosa sisemisele raadiusele. See mõõdetakse painde sisemisest kõverusest materjali paksuse keskjooneni.

Terav painde (väike raadius): Peaaegu nulliline raadius, nõuab sageli erialast tööriista.

Standardne paine (mõõdukas raadius): levinud enamikus rakendustes.

Suure raadiusega paine: kasutatakse esteetilistel või konstruktsioonelisel põhjustel.

Olulisemad tegurid, mis mõjutavad paineraadiust

1. Materjali omadused

a) Materjali tüüp

Erinevatel metallidel on erinevad duktiilsus- ja pikenemisomadused:

Alumiinium: duktiilsem, võimaldab tihedamaid paineid.

Rohke teras: kõvem, nõuab suuremaid paineraadiusi pragunemise ennetamiseks.

Kõrb teras: mõõdukas paindlikkus, laialdaselt kasutuses standardrakendustes.

Vask ja messing: väga duktiilsed, sobivad tihedatele raadiustele.

b) Materjali paksus (T)

Üldreegel: Minimaalne painderaadius ≈ 1×T (pehmade materjalide puhul) kuni 2×T (kõvemate materjalide puhul).

Näide:

2 mm alumiinium → Minimaalne raadius = 2 mm (1×T).

2 mm roostevaba teras → Minimaalne raadius = 4 mm (2×T).

c) Teravate suund (anisotroopsus)

Teravatele paralleelne painutamine suurendab pragunemise ohtu.

Teravatele risti painutamine võimaldab kitsamaid raadiuseid.

2. Tööriistade ja masinate võimalused

a) Nokk ja maatriks valik

Väiksemad V-maatriksite avausega saab teostada täpsemat painutust, kuid suurendab vajalikku tonnida.

Suuremad maatriksid toodavad suuremaid raadiuseid, kuid vähendavad materjali pinnale avalduvat survet.

b) Press Brake Tonnage

Kõrgema tonniga masinad saavutavad paksemates materjalides täpsemaid paindeid.

Vähese tonniga tekivad ebatäielikud pained või tagasilöök.

c) Tööriista materjal ja kulumine

Kulunud või kriimustunud matritsid suurendavad pinddefektide tekkeriski.

Kõrbetud terastööriistad säilitavad täpsust pikema kasutusaja jooksul.

3. Paindmine

Õhu paindmine: Kasutab väiksemat põrkeradiust, mis annab loomuliku painderaadiuse, mis sõltub materjali elastsusest.

Põhja saamine / mündi valmistamine: Surub materjali matritsi, loob täpsema raadiuse, kuid nõuab kõrgemat tonniga.

Rullipaindmine: Kasutatakse suurte raadiustega kõverate (nt silindrite) jaoks.

4. Painde nurk ja tagasipöördumise efekt

Täpsemad painded (teravad nurgad) nõuavad väiksemaid raadiuseid, kuid võivad suurendada tagasipöördumist.

CNC-programmeerimisel tuleb arvestada tagasipöördumise kompenseerimist.

5. Pindapuuja ja katoodkaitse kaalumised

Värvitud või katsutud lehed võivad murduda, kui neid liiga teravalt painutada.

Eelpainde töötlemine (nt valmistamine) võib parandada kujundatavust.

Minimaalse painderaadiuse arvutamine

1. Empeeriline valem

Minimaalse painderaadiuse (R_min) saab hinnata järgmiselt: Rmin=K×T

Kus:

K = Materjali tegur (0,5 pehmale alumiiniumile, 2 roostevabale terasele).

T = Materjali paksus.

2. Tööstusstandardid (Näidisjuhised)

| Materjal | Soovitatav miinimalne painderaadius |

| Pehm Alumiinium | 0,5× T |

| Kõrb | 1× T |

| Rosteel | 2× T |

| Kupar | 0,8× T |

Levinud vigased painderaadiused

Pragu (painde välimine külg): Põhjustatud liigse õhke vähenemise tõttu.

Korts (pöördenurga sees): Liiga suur raadius õhukeses lehtmetallis.

Elastiline tagasipöördumine: Materjal pöördub kergelt tagasi pärast paindumist, mis mõjutab täpsust.

Pindkriimustused: Vale tööriistade valikust või nõrgast määrduvusest.

Parimad tavased optimaalse painderaadiuse valimiseks

Vaata materjaliandmetelehe pealt pikendus- ja K-teguri väärtusi.

Kasuta sobivat tööriista (õige V-tööriistalaua laius, punch raadius).

Tee katsetusi enne täisvalmistust.

Rasvata, et vähendada hõõrdumist ja pragunemist.

Kaalu järeltöötlemist (pinge kõrvaldamine, ummistuse eest vabanemine).

Kohustuslik väljaandmine

Lehtmetalli painderaadius määratakse materjali omaduste, paksuse, tööriistadega ja paindumismeetodiga. Õige valik tagab struktuurilise terviklikkuse, vähendab vigastusi ja parandab valmistatavust. Järgides tööstusjuhiseid ja tehes katsetusi, saavad tootjad optimeerida oma paindumisprotsessi kõrgekvaliteediliste tulemuste saamiseks.