¿Qué afecta la vida útil de una cizalla?

Antes de invertir en una guillotina, comprender plenamente los factores que influyen en su durabilidad es clave para tomar una decisión informada. Esta guía proporcionará respuestas completas a sus preguntas sobre los factores que determinan la vida útil de una guillotina y cómo extenderla eficazmente. Detallaré los factores clave que afectan la vida útil de las guillotinas, compartiré consejos prácticos de mantenimiento y propondré una serie de estrategias proactivas de gestión para garantizar que su equipo permanezca eficiente y estable a largo plazo.

Factores clave que afectan la vida útil de la máquina de corte

Calidad de la máquina y estándares del fabricante

La durabilidad de una tijera depende del momento en que la adquiere. Elegir equipos de alta calidad de un fabricante reconocido significa que está invirtiendo no solo en la máquina en sí, sino también en su construcción robusta, componentes confiables y piezas fabricadas con precisión. Equipos de menor precio pueden ahorrar dinero inicialmente, pero a largo plazo suelen implicar costos más altos de mantenimiento y una vida útil más corta.

Frecuencia e Intensidad de Uso

La vida útil de una tijera se ve directamente afectada por la intensidad y frecuencia de su uso. Una máquina que opere continuamente bajo cargas elevadas se desgastará naturalmente mucho más rápido que una que opere solo intermitentemente. Seguir estrictamente los procedimientos de operación recomendados por el fabricante es fundamental para retrasar eficazmente el envejecimiento del equipo y prolongar significativamente su vida útil.

Tipo y espesor del material procesado

La vida útil de una guillotina está directamente afectada por el tipo y espesor del material que se procesa. El procesamiento prolongado de materiales que exceden la capacidad nominal de la máquina puede acelerar el desgaste, incrementar el estrés en los componentes e incluso provocar fallos prematuros, reduciendo la vida útil del equipo. Por lo tanto, es crucial adherirse estrictamente a las especificaciones del equipo y asegurar que todas las operaciones se realicen dentro de la capacidad recomendada para garantizar un funcionamiento prolongado y confiable.

Instalación y configuración adecuadas de la máquina

Una instalación incorrecta puede limitar directamente la vida útil de tu guillotina. La máquina debe colocarse firmemente sobre una base nivelada y sólida. Una instalación y alineación precisas ayudan a suprimir vibraciones y tensiones innecesarias, reduciendo eficazmente el desgaste de los componentes y asegurando un funcionamiento estable y prolongado.

Medidas básicas de mantenimiento para extender la vida útil de las guillotinas

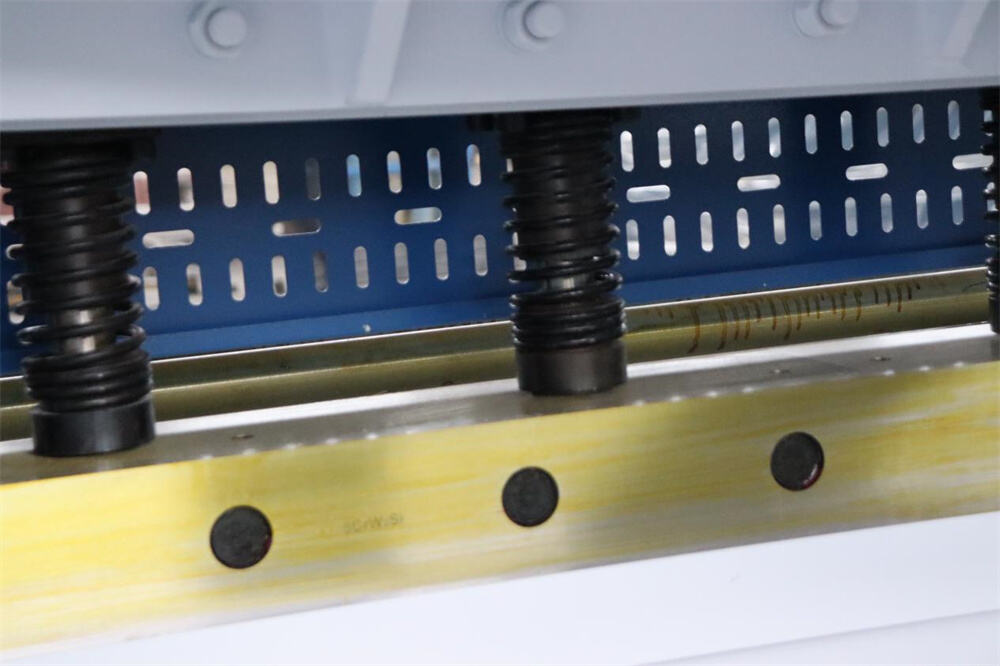

Inspección regular de las cuchillas y componentes

La inspección regular de las cuchillas de corte y los componentes relacionados es fundamental para identificar el desgaste. Mantener las cuchillas afiladas no solo garantiza un corte limpio y preciso, sino que también reduce eficazmente la carga sobre la máquina. Por el contrario, cuchillas desgastadas requieren mayor presión para completar el corte, lo que incrementa el desgaste de los componentes y acorta la vida útil de la máquina.

Programa eficaz de lubricación

La lubricación regular de las piezas móviles es una medida clave para garantizar el correcto funcionamiento de la máquina de corte y reducir los daños por fricción. Seguir el plan de lubricación establecido por el fabricante y utilizar el tipo de lubricante especificado puede mejorar eficazmente la confiabilidad en la operación del equipo y prolongar significativamente su vida útil.

Limpieza y eliminación de escombros

Durante el funcionamiento normal de cizallado, el polvo, los residuos y las partículas se acumulan, lo que potencialmente puede causar atascos mecánicos, malas conexiones eléctricas y otros problemas. Una limpieza regular y exhaustiva es clave para mantener un funcionamiento óptimo del equipo y prevenir eficazmente la corrosión o daños en los componentes causados por la acumulación de contaminantes.

Cómo el entorno de operación afecta la vida útil de la cizalla

Temperatura y niveles de humedad

Un entorno con temperaturas y humedad inadecuadas puede causar daños permanentes a los sistemas electrónicos y a la estructura mecánica de la cizalla. Las temperaturas extremas o una alta humedad pueden provocar fácilmente óxido, corrosión y degradación de los componentes, aumentando significativamente el riesgo de fallos en el equipo. Por lo tanto, se recomienda operar las cizallas en un entorno estable con temperatura y humedad controladas para ayudar a mantener su fiabilidad y vida útil a largo plazo.

Espacio de trabajo limpio y organizado

Mantener tu área de trabajo limpia y ordenada no solo ayuda a garantizar la seguridad operativa, sino que también mejora el rendimiento del equipo. Al controlar eficazmente los efectos de contaminantes como el polvo y la suciedad, puedes reducir el desgaste anormal de los componentes de la máquina, extendiendo significativamente la vida útil de tu equipo.