Bakit mahalaga ang tumpak ng rolling mills?

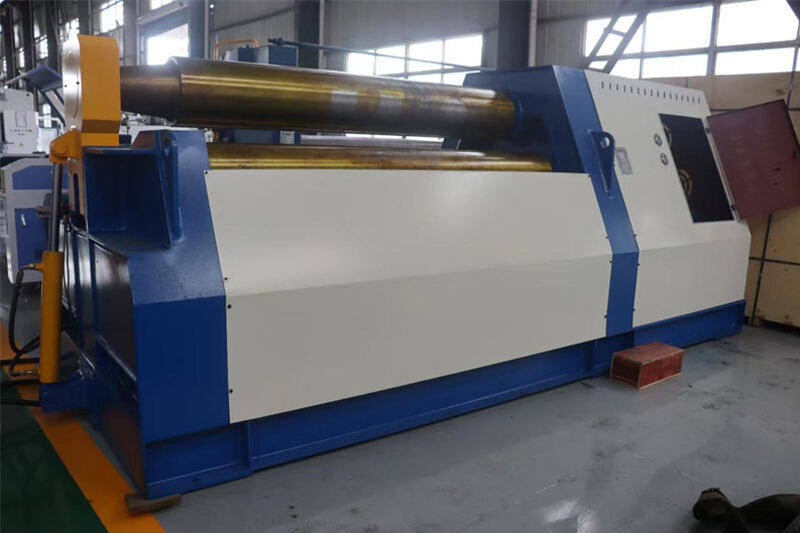

Tuwing naghahanda ng mga materyales para sa kritikal na mga gawain sa pagmamanupaktura, lagi kong naiisip ang pangunahing halaga ng katumpakan ng roller mill: ito ay hindi lang isang pasugtanin, kundi isang direktang pamantayan para sa katumpakan ng mga bahagi, basura ng materyales, at kahusayan ng produksyon. Ang gabay na ito ay magpapaliwanag kung paano mapapabuti ang kalidad ng produkto, mababawasan ang rate ng basura, at matitiyak na ang iyong tindahan ay natutugunan ang pinakamahihigpit na espesipikasyon ng mga customer sa pamamagitan ng pagtugon sa mahigpit na toleransiya at patuloy na kalibrasyon ng iyong mga makina.

Ang impluwensya ng katumpakan ng rolling machine sa kalidad ng bahagi

Pag-unawa sa mga kinakailangan sa toleransiya ng mga naidukot na bahagi

Ang bawat proyekto ay may tiyak na tolerance - ang halaga ng paglihis mula sa pinahihintulutang nominal na sukat. Kapag gumagawa ng cylindrical shells o curved panels, mahigpit na kontrol sa tolerance ang susi para matiyak na ang huling hugis ay tumutugma sa layunin ng disenyo. Gamit ang mga precision rolling mills, nakakamit ko ang ±0.5 mm na kinakailangan sa straightness o roundness na karaniwan sa aerospace at automotive na aplikasyon.

Bawasan ang basura at scrap ng materyales

Ang hindi tumpak na rolling ay nagreresulta sa rework o scrap. Nakita ko ang mga shop na bawasan ang scrap ng hanggang 30% sa pamamagitan lamang ng pagpapatupad ng tumpak na kontrol sa posisyon ng backgauge at synchronized roll positioning. Sa pamamagitan ng pagpapanatili ng mga paulit-ulit na setup, minimitahan ko ang mga sira at binabawasan ang gastos sa materyales.

Mga pangunahing teknolohiya para mapabuti ang katiyakan ng rolling mill

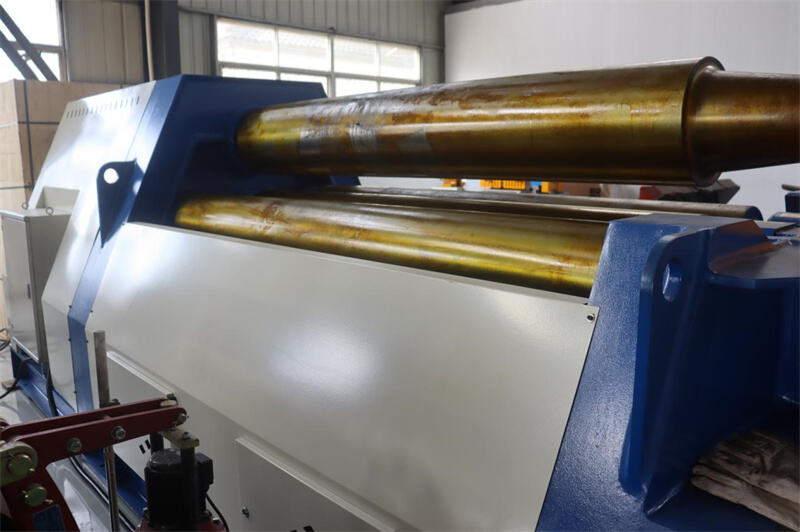

Regular na calibration ng roll gap at back gauge

Ang pagpepelsa ng roll gap ay nagpapaseguro na ang sheet ay magde-deform nang pantay-pantay sa bawat pass. Araw-araw kong ginagawa ang monthly calibration gamit ang feeler gauge at dial indicator upang i-verify ang roll gap. Pagkatapos, aayusin ko ang back gauge stop upang panatilihin ang sheet feed position sa loob ng 0.2 mm mula sa target setting.

Paggamit ng closed-loop feedback control

Ang mga modernong mills na may kabit na closed-loop servo motors at laser displacement sensors ay nagpapahintulot sa akin na subaybayan ang real-time position data. Kapag pinagana ko ang closed-loop feedback, ang controller ay awtomatikong bubura sa mga paglihis, nagbibigay ng pare-parehong curvature kahit sa ilalim ng magkakaibang kondisyon ng karga.

Paglalagay ng lubricant at paglilinis para sa maayos na operasyon

Isang malinis at maayos na na-lubricate na makina ay mas maayos ang takbo. Ilalapat ko ang inirekomendang lubricant ng manufacturer sa lahat ng moving joints at panatilihin kong malinis ang roller surfaces. Ang simpleng kasanayang ito ay nakakapigil sa hindi pantay na paggalaw ng roller at nagpapanatili ng tumpak na calibration.

Pamalit ng mga nasirang bahagi bilang pag-iingat

Ang mga roller sleeve, seals at hydraulic hoses ay sumisira sa paglipas ng panahon. Sa pamamagitan ng pagpoprograma ng mga paunang pagpapalit batay sa datos ng lifespan, maaari kong maiwasan ang hindi inaasahang mga pagkabigo na maaaring makompromiso ang katiyakan.