איך מחליפים טבעות חותמות של צילינדר במכונות כפיפה ממוחשבות?

תוכן העניינים

חלק 1: כוונון מדריך

○ חותם מנקה

○ התקנה נכונה של חותמי ניקוי והפיכת כוונון המדריך

○ חוגה גומית

○ התקן את החוגה הגומית בחלק החיצוני

○ חותם מדרגה

חלק 2: פיסטון

○ חוגה חלקה

חלק 3: שילוב

ремבלט להדרכה

מתקנים חגורות להדרכה על הפיסטון עם שמן הידראולי

○ מיקום נכון של הפיסטון בצילינדר

התקן כוונן להדרכה

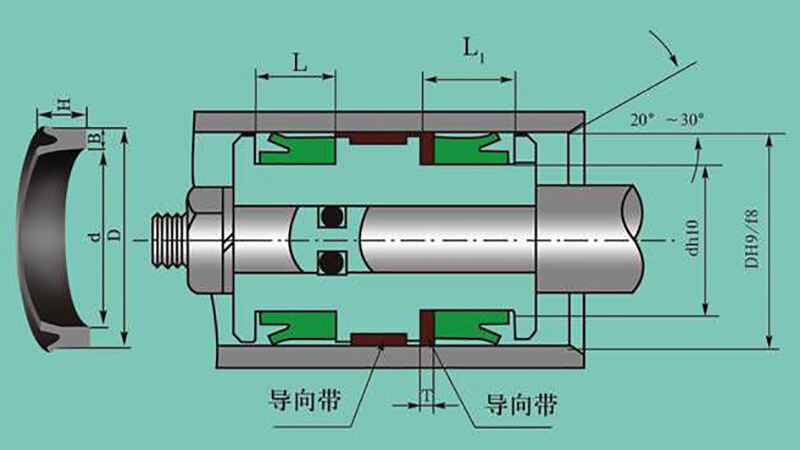

○ חוגות פטנט צילינדר במכונת כפיפה CNC

איך מוסרים את הכוורת והפיסטון

הקדמה

האם צילינדרים שמדליפים משפיעים על ביצועי מכונת הכפיפה שלך? החלפת חוגות הפטנט היא הכרחית לשיקום הדיוק ולמניעת אובדן שמן הידראולי.

החלפת חוגות הפטנט בצילינדרים של מכונות כפיפה CNC מבטיחה לחץ הידראולי תקין, ומניעה דליפות יקרות ופסדי זמן עבודה. למדו את הצעדים להחלפת החוגות באופן יעיל וממשיכו את חיי המכונה שלכם.

חלק 1: כוונון מדריך

חתימה מסורבבת

חוגה ניקוי היא רכיב קריטי במכונות כפיפה CNC, שנועדה למנוע חדירת מזונות כמו אבק, עפר ושבבי מתכת לתוך הצילינדר ההידראולי. היא ממוקמת בקצה החיצוני של הצילינדר, ומבטיחה תנועה חלקה של הפיסטון על ידי הסרת הפסולת, ובכך מאריכה את חיי החוגה ושמורה על יעילות הידראולית.

חותמות מנגבנים עשויות מחומרים עמידים כמו פוליוריתן או גומי ניטריל כדי לעמוד בסביבות לחץ גבוה. בדיקת קבועה והחלפת בזמן של חותמות מנגבנים משומשות עוזרות למנוע דליפות הידרוליקות ובעיות ביצועים. תחזוקה נכונה מבטיחה דיוק עיקול עקבי, מקצרת זמן הפסקות ומגדילה את אורך החיים הכולל של הבלם.

התקנת חותמות המנגבאות והפכת שרוול המדריך כראוי

ודא שהחצובה הכפולה של חותמת המנגל פונה לצד הנפט לפני ההתקנה. בקפידה לחץ את חותמת המנגב לתוך הקצה המיועד, כדי לוודא שהיא תואמת בצורה בטוחה ובשוויון. חזור על התהליך עבור חותם המנגב השני, בדוק מיקוד והעמדה.

ברגע ששני חותמות המנגב מתקינות, הפוך את שרוול המדריך ב 180 מעלות כדי להשלים את ההגדרה. שלב זה מבטיח מיקום חותם נכון עבור ביצועים אופטימליים ומונע דליפת שמן. בדוק פעמיים את ההתקנה כדי לוודא שהחותמים יושבים היטב והכיסוי המנחה מכוון כראוי לפני ההמשך.

עיגול גומי

טבעות O הן רכיבי חותם חיוניים בצילינדרים הידראוליים של מכונות כפפות CNC, ומונעות דליפת נוזל ומבטיחות פעולה יעילה. הן מיוצרות מחומר עמיד כמו גומי או חומרים סינתטיים, ומתאימות בצורה צמודה בין רכיבים מתכתיים, שומרות על לחץ וממזינות בלאי.

במהלך הזמן, טבעות O עשויות להשתנות עקב לחץ גבוה, תנודות טמפרטורה או זיהום, מה שעלול לגרום לחוסר יעילות הידראולית. בדיקה תקופתית והחלפה בזמן של טבעות O משולשות היא הכרחית לשמירה על תפקוד המחרשה. בחירת טבעות O באיכות גבוהה עם התנגדות מתאימה לשמן ולחום מאריכה את חיי הרכיבים ההידראוליים, ומבטיחה פעולה חלקה של מכונת הכפפה.

התקן את טבעת ה-O בחלק החיצוני

כדי להבטיח חותם תקין ולמנוע דליפות הידראוליות, התקן את טבעת ה-O בצורה זהירה בחלק החיצוני של הצילינדר. עקוב אחר הצעדים הבאים:

1. נקה את הקונדס באופן מעמיק כדי להסיר אבק, שברי נזקים או חומר חותם ישן.

2. הצב שכבת דקה של שמן הידראולי או שמן יסוק על טבעת ה-O כדי להפחית החיכוך.

3. מתח בעדינות ומקם את האן-רינג בחריצה, ודא שהוא יושב בצורה שווה מבלי להסתבך.

4. לחץ אותו חזק למקומו, ועם אותו הזמן ודא שהוא מיושר בצורה מושלמת עם משטח החותם.

אן-רינג מותקן כראוי מגביר את יעילות מכונת השיבוץ, מונע דליפות, ומאריך את חיי הצילינדר.

חותם שלב

חותם סטפ הוא רכיב חיוני בצילינדרים הידראוליים של מכונת שיבוץ CNC, שפותח ליחות אטימה יעילה וצמיגות נמוכה. הוא מורכב מאלמנט אטימה PTFE בצירוף אן-רינג אלסטי, ודואג למשיכות גבוהה ומניעת דליפות תחת לחץ קיצוני.

הצורת סטפ הייחודית עוזרת בשמירה על שימון אידיאלי, מפחיתה שחיקה ומאריכה את חיי השירות של הצילינדר. חותמי סטפ משמשים לרוב במערכות הידראוליות ופנומטיות ביצועיות גבוהות, בהן דיוק ואמינות קריטיים.

טיפ להתקנה:

1. התקן תחילה את האן-רינג של חותם הסטפ.

2. לאחר מכן, התקן את טבעת הבֶּלֶן עם הצעד הקטן פונה לצד השמן.

בדיקת קבועה וחיליפת חותמות שלבושות עוזרות לשמור על דיוק מכונית עקבי ומונעות דליפת נוזל הידרולי.

חלק 2: פיסטון

גליד רינג

טבעת הגליד היא חותם הידרולי בעל ביצועים גבוהים המיועד לצילינדרים של בלמים וליישומים תעשייתיים אחרים. הוא כולל עיצוב עם חיכוך נמוך, המבטיח תנועה חלקה תוך שמירה על חותם הדוק כדי למנוע דליפת שמן.

עשוי מחומרים מבוססי PTFE, הטבעת Glyd מספקת עמידות לשרידה מצוינת, מה שהופך אותו אידיאלי עבור לחץ גבוה ופעולות במהירות גבוהה. שילובו של טבעת O אלסטומרית ופלפל פטף אבן חותמת מבטיח יעילות חותמת גבוהה וחיי שירות ארוכים.

שלבי התקנה:

1. משרד החוץ תחילה תקין את הטבעת.

2. משרד החוץ קח את טבעת החותם לתוך הקניון באמצעות מברג אחד (ממנע מגרד את הטבעת).

3. מה? סובב את הפיסטון כדי להשלים את ההתקנה.

חותם אמין זה משפר את יציבות הפעולה ומפחית את עלויות התחזוקה במערכות הידרוליקות.

חלק 3: שילוב

חגורה מדריך

ремית ההדרכה במכונת קיפול מבטיחה קיפול מדויק ויציב. היא מספקת תנועה חלקה ומבוקרת של המטחן, מפחיתה החיכוך והבלי, ומשמרת את הדיוק. היצרנית מחומרים עמידים וחזקים, ремית ההדרכה מאריכה את חיי המכונה ומשפרת את הביצועים.

טיפ להתקנה:

1. למשוח שמן באופן שווה ודק לפני התקנת ремית ההדרכה.

2. לחזור ולמשוח שמן לאחר ההתקנה לצורך שימון ומניעת חלודה.

התקנת ремיות היגוי על הפיסטון עם שמן הידראולי

1. למשוח שכבה דקה ושוות של שמן הידראולי בתחתית הפיסטון כדי להפחית החיכוך.

2. להניח את שתי ремיות ההדרכה סביב הפיסטון, תוך ודאות על התאמה צמודה וalinיאציה נכונה.

3. לבדוק את האליניאציה ולאשר שה ремיות מותקנות היטב לפני המשך.

ремיות הללו מיציבות את הפיסטון בתוך הגליל, מונעות בלאי מוגזם ומבטיחות ביצועים אופטימליים.

יישור הפיסטון בצורה הנכונה בתוך הגליל

1. להכניס את הפיסטון בצורה חלקה לתוך הגליל כדי למנוע נזק לחוגות האטימה.

2. התאם את הפיסטון כך שהחורים התאומים שלו יופנו קדימה ואחורה של הגליל.

3. בדוק אם יש מכשולים או אי-התאמה במיקום.

4. הכנס שמן הידראולי כדי להפחית החיכוך אם נדרש.

מיקום נכון משפר את היעילות ומחזק את אורך חיי הצילינדר.

התקן את כפפת המדריך

1. נקה היטב את הגליל מבפנים.

2. התאם את כפפת המדריך לכניסה הגליל והכנס אותה בצורה אחידה.

3. השתמש בכלי מתאים כדי לדחוף את הכפפה למקום עם לחץ אחיד.

4. בדוק שוב את המיקום וфикס אותה לפני הרכבה מחדש.

כפפת מדריך מותקנת כראוי שיפור את יעילות החותם ופוחתת את הבلى.

טבעות חיבוי צילינדר ברגים במכונות כפיפה ממוחשבות

טבעות חיבוי צילינדר ברגים נועדו להתקנה בטוחה ותחזוקה נוחה. מברגים לצלינדר, הן מוודאות חיבוי צמוד למניעת דליפת שמן הידראולי ולשמירה על לחץ עקבי.

נקודות מפתח:

להחליף טבעות נבליות מיד כדי לשמור על יעילות.

למנוע חיזוק יתר במהלך ההתקנה.

להשתמש בטבעות איכותיות المتوאימות עם דגם מכונת הכפיפה שלך.

בדיקה שוטפת עוזרת לגילוי מוקדם של דליפות או התדרדרות.

איך מוסרים את הכוורת והפיסטון

כדי להסיר את שרוול המדריך והפלגון:

1. לברג שני ברגים בנקבים הטכנולוגיים.

2. למשוך החוצה באמצעות עגלה אווירית.

טיפים כלליים לתחזוקת צילינדרי שמן הידראולי

1. בדקו את רמת השמן בקבוע כדי להבטיח שהיא ברמה הנכונה. שמן נמוך יכול לפגוע בצילינדר.

2. שנו את השמן מעת לעת כדי למנוע זיהום ולהאריך את חיי הצילינדר.

3. בדקו אם יש דליפות וטפלו בהן מיד כדי למנוע נזקים נוספים.

4. בדקו את החותמים מעת לעת עקב בلى או נזק, והחליפו אותם לפי הצורך.

5. שמרו על ניקיון הצילינדר כדי למנוע זיהום.

6. השתמשו בשמן הידראולי הנכון המומלץ על ידי JUGAO ליישום הספציפי שלכם.

בעקבות טיפים אלו, תוכלו להבטיח שהצילינדרים שלכם יפעלו בתפוקה גבוהה ויארכו ימים.