NC Press Brake Cylinder Seal Ring Replacement Guide

Is your NC press brake showing signs of leakage or reduced performance?

Replacing the cylinder seal rings can restore equipment efficiency and avoid

costly repair losses. As a key maintenance operation to ensure hydraulic

pressure and prevent leaks, replacing the cylinder seal rings of an NC press

brake is a simple yet crucial step that is vital for the smooth operation and

extended service life of the equipment.

Seal rings are prone to wear and aging due to long-term exposure to high pressure, high temperature, and friction, which can lead to hydraulic oil leakage and poor equipment performance. Below is a detailed guide on the safe and efficient replacement of NC press brake cylinder seal rings.

I. Safety First

Before starting any work, ensure that the hydraulic system is fully depressurized and the equipment is powered off. Meanwhile, wear professional protective gear such as gloves and goggles to ensure operational safety.

II. Gather Necessary Tools

Prepare wrenches, screwdrivers, pliers, a seal puller, a hammer, and replacement seal rings in advance. Note that the replacement seal rings must be accurately matched to the cylinder model to avoid compromising the sealing effect due to mismatched specifications.

III. Access the Cylinder

Depending on the specific structure of the equipment, it may be necessary to remove protective covers, housings, or other related components to smoothly access the cylinder.

IV. Release Pressure and Disconnect

If the cylinder is still under pressure, use professional methods to release the pressure to prevent potential safety hazards caused by residual pressure. Subsequently, disconnect all hydraulic hoses and connectors attached to the cylinder.

V. Remove the Cylinder

According to the equipment installation method, unscrew the bolts fixing the cylinder and remove the cylinder from the mounting bracket or connection point. Note that the cylinder is heavy; handle it with care during removal to avoid collisions or personal injuries.

VI. Disassemble the Cylinder

After removing the cylinder, disassemble it carefully. During the disassembly process, carefully record the installation sequence of each component and the orientation of the seal rings to provide a reference for subsequent reassembly.

You can refer to relevant videos to disassemble the cylinder components in order: first move the piston rod downward to a position where it cannot move, unscrew the set screws, and then remove the nut and piston cap inside the piston rod. When disassembling, all components and screws must be loosened in a counterclockwise direction.

The distribution of seals in each part of the cylinder is as follows:

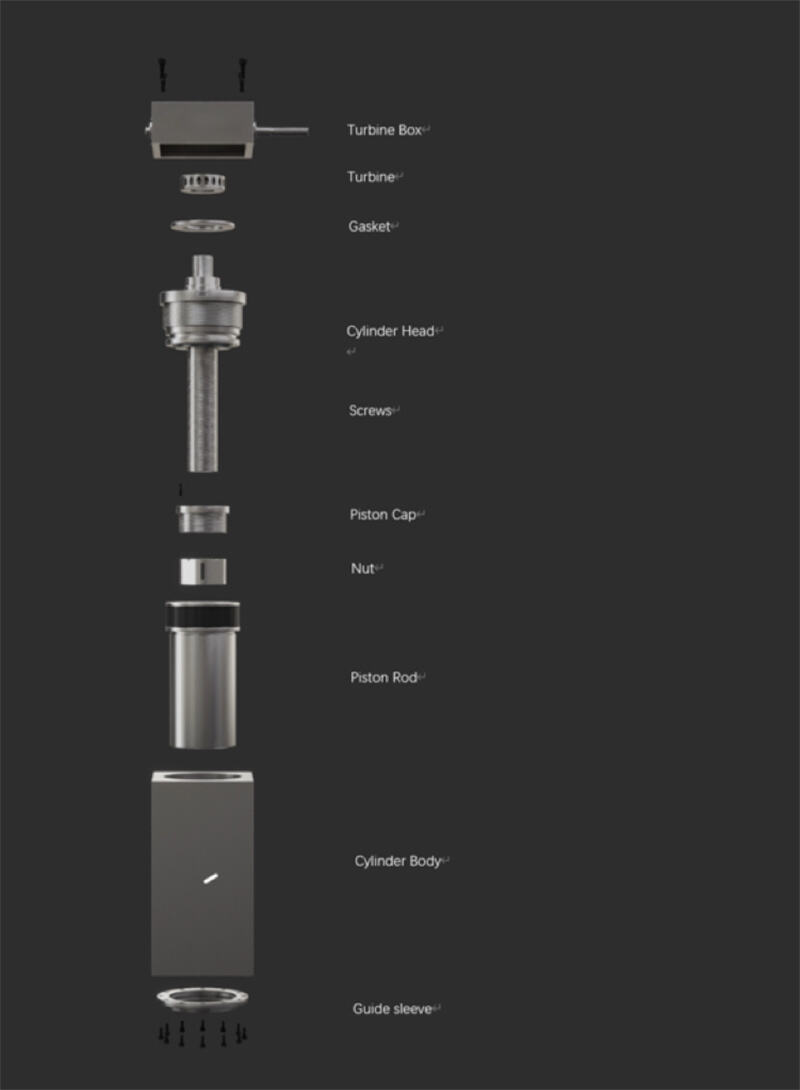

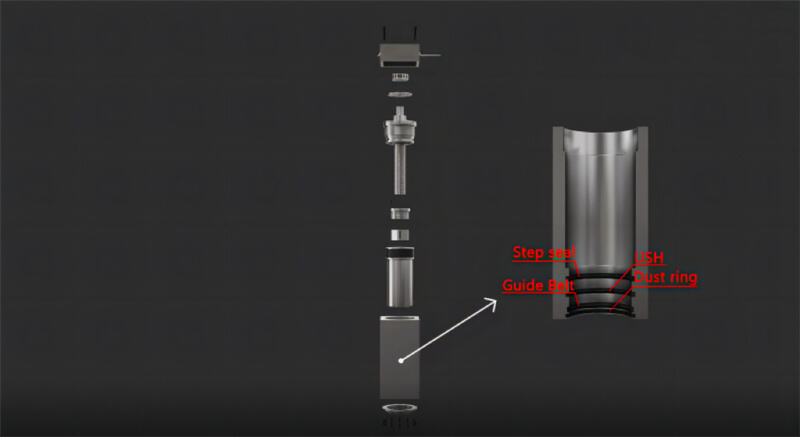

1. The cylinder body is equipped with step seals, USH seals, guide belts, and dust rings (See diagram: JUGAO related components: Cylinder Body, Guide Sleeve, Piston Rod, Nut, Piston Cap, Screws, Cylinder Head, Gasket, Turbine, Turbine Box);

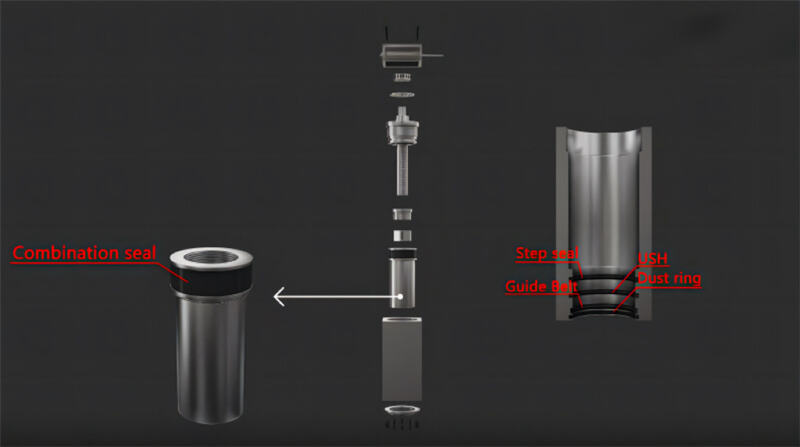

2. The top of the piston rod is equipped with combination seals (See diagram: JUGAO related components: Step Seal, USH Seal, Dust Ring, Guide Belt);

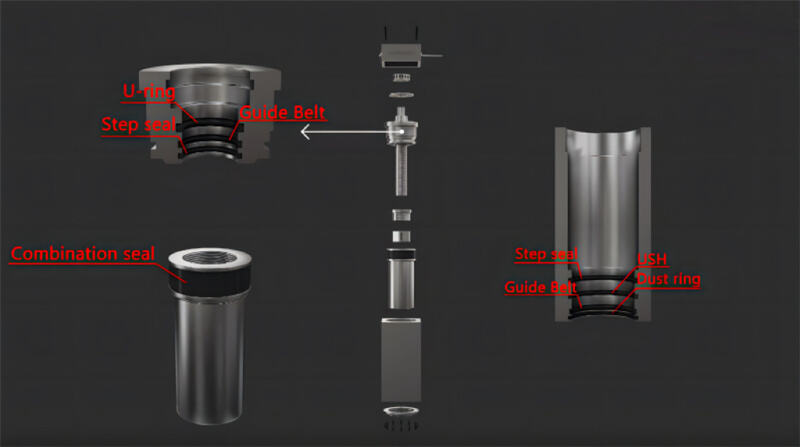

3. The cylinder head is equipped with step seals, U-rings, and guide belts (See diagram: JUGAO related components: Combination Seal, Step Seal, USH Seal, Dust Ring, Guide Belt);

4. All components must be reassembled in the "reverse order of installation and disassembly" (See diagram: JUGAO related components: U-ring, Guide Belt, Step Seal, Combination Seal, Step Seal, USH Seal, Dust Ring, Guide Belt).

(I) Remove Old Seals

Use a seal puller or a suitable tool to carefully remove the old seals. Operate with gentle force to avoid scratching the cylinder bore or damaging other components.

(II) Clean and Inspect

Thoroughly clean the cylinder bore and all disassembled components to remove oil stains, impurities, and residual sealant. At the same time, carefully check each component for wear, deformation, or damage. If any issues are found, replace them in a timely manner to avoid seal failure caused by component defects.

(III) Install New Seals

Lubricate the new seals with hydraulic oil and carefully install them in the designated positions. Ensure that the seals are properly seated and not twisted to guarantee sealing performance.

(IV) Reassemble the Cylinder

Reassemble the cylinder components in the reverse order of disassembly. Tighten the bolts strictly in accordance with the manufacturer's specified standards to avoid affecting equipment operation due to loose or over-tightened bolts.

(V) Reinstall the Cylinder

Reinstall the reassembled cylinder onto the equipment, connect the hydraulic hoses and connectors, and ensure that all components are firmly fixed without loosening.

(VI) Test Operation

After reassembly is complete, start the equipment for testing to check if the cylinder operates smoothly and if there are any leaks in the hydraulic system. If any abnormalities are found, stop the machine immediately to troubleshoot.

VII. Daily Maintenance Tips for Hydraulic Cylinders

Proper daily maintenance of hydraulic cylinders can effectively ensure their working efficiency and extend their service life. Below are some general maintenance suggestions:

1. Regularly check the oil level: Periodically check the hydraulic oil level in the cylinder to ensure it is within the specified range. A too-low oil level can easily cause cylinder damage and affect the normal operation of the equipment;

2. Change hydraulic oil on time: To prevent contamination and deterioration of hydraulic oil, replace it regularly. The frequency of oil changes should be flexibly adjusted according to the equipment's usage scenario and operating conditions;

3. Regularly check for leaks: Periodically inspect the cylinder and hydraulic system for leaks. If any leaks are found, address them immediately to avoid hydraulic oil waste and damage to equipment components;

4. Inspect the condition of seal rings: Regularly check the seal rings for wear, aging, and damage. Replace any problematic seal rings in a timely manner to prevent leaks caused by seal failure;

5. Keep the cylinder clean: Regularly wipe the surface of the cylinder with a clean cloth to remove dust, oil stains, and other impurities, avoiding contaminants from entering the cylinder and causing damage;

6. Use specified hydraulic oil: Strictly use the hydraulic oil recommended by the manufacturer that is compatible with the cylinder and equipment. Do not use hydraulic oil of incorrect specifications, as this may damage the cylinder and other components of the hydraulic system.

By following the above maintenance suggestions, you can effectively ensure the stable operation of hydraulic cylinders, extend their service life, and provide reliable support for the efficient operation of NC press brakes.