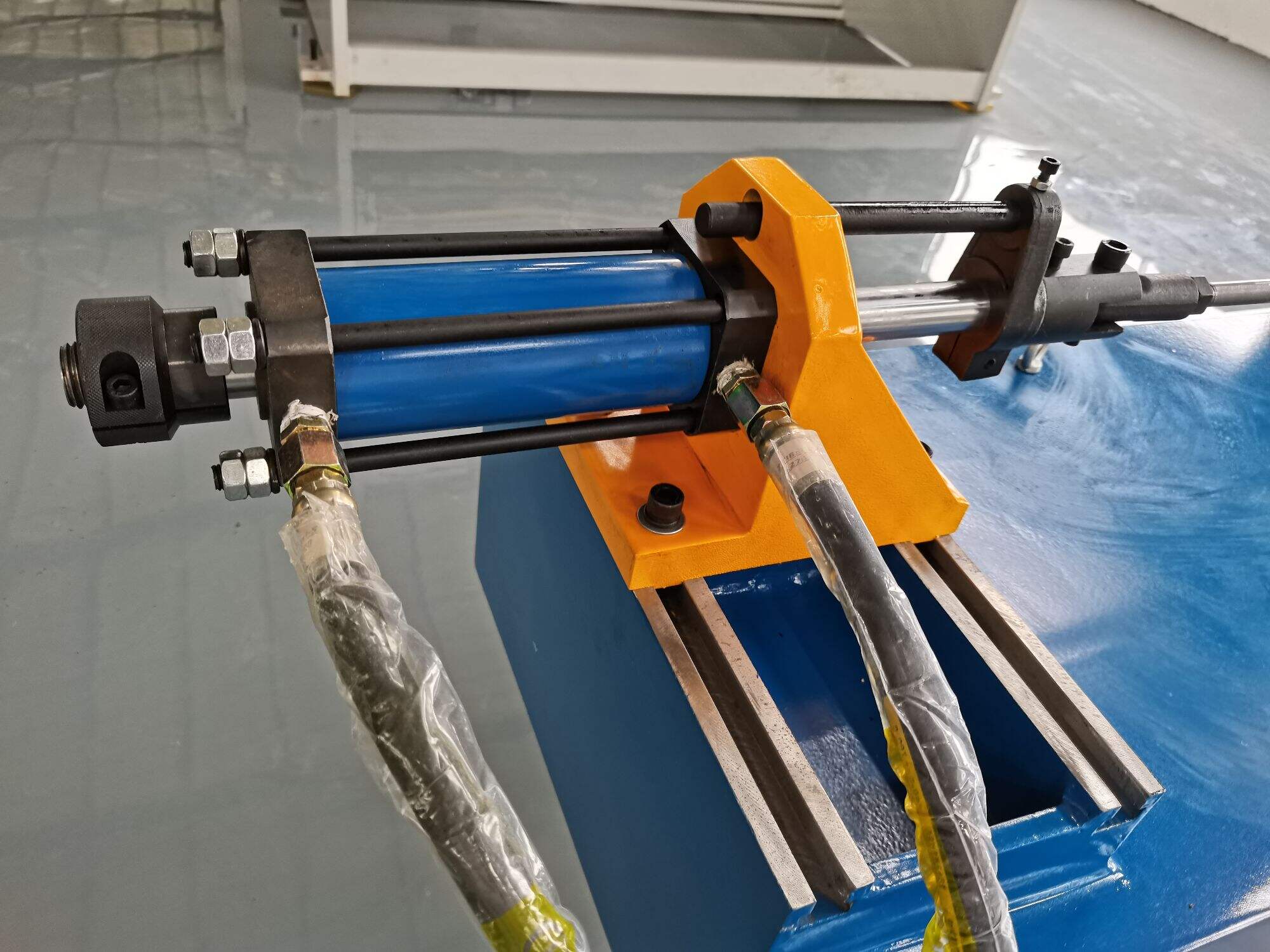

हम विभिन्न प्रकार की चीजों के लिए धातु को मोड़ते हैं, लेकिन कभी-कभी वह ठीक से नहीं मुड़ता जैसा हम चाहते हैं। इसे स्प्रिंग बैक कहा जाता है। यदि आप धातु को मोड़ने का प्रयास करते हैं, तो धातु वापस अपनी सीधी स्थिति में आना चाहेगा। यह परेशान करने वाला हो सकता है और जब आपको सटीकता की आवश्यकता होती है तो निश्चित रूप से निराशाजनक हो सकता है। सौभाग्यवश, विशेष मोड़ने की मशीनें इसकी सहायता के लिए उपलब्ध हैं! जैसे JUGAO जैसी कंपनियों ने ऐसी मशीनों को डिज़ाइन किया है जिनमें विशेष नियंत्रण होते हैं जो इस स्प्रिंग बैक के लिए समानुरूपण कर सकते हैं। यह धातु को मोड़ना संभव बनाता है और फिर इसे बिना अधिक प्रयास के आपके आकार में बनाए रखता है। तो आप इन मशीनों को कहाँ प्राप्त कर सकते हैं, और आपको यह कैसे निर्धारित करना चाहिए कि आपकी आवश्यकताओं के लिए कौन सी मशीन सही है?

सटीक स्प्रिंगबैक सुधार के लिए अत्याधुनिक मोड़ने की मशीनें कहाँ प्राप्त करें

समकालीन बेंडिंग मशीनों की खोज में, कई स्थान दिमाग में आते हैं। सबसे पहले, ट्रेड शो एक अच्छा तरीका हो सकता है। ये उद्योग के आयोजन होते हैं जिनमें धातु बेंडिंग से लेकर सभी नवीनतम तकनीकों को प्रदर्शित किया जाता है। आप मशीनों को कार्यरत देख सकते हैं, और विशेषज्ञों से बात कर सकते हैं जो आपको बता सकते हैं कि वे कैसे काम करती हैं। इंटरनेट पर खोज करना भी विचार करने योग्य है। उद्योग उपकरणों में विशेषज्ञता रखने वाली वेबसाइट्स अक्सर सर्वश्रेष्ठ मशीनों की सूची प्रदान करती हैं झुकने की मशीन . आप समीक्षाएँ भी पढ़ सकते हैं और विशेषताओं की तुलना कर सकते हैं। JUGAO की वेबसाइट एक अच्छा प्रारंभिक बिंदु है, क्योंकि इसमें उस तकनीक को शामिल किया गया है जो स्प्रिंगबैक को आसान बनाती है। और इस बात की संभावना है कि स्थानीय वितरकों के पास शोरूम होंगे जहां आप खरीदने से पहले मशीनों का परीक्षण कर सकते हैं। यहां व्यावहारिक अनुभव प्राप्त करने का अवसर वास्तव में मूल्यवान हो सकता है। व्यापार पत्रिकाओं को भी न भूलें, जो नई मशीनों पर भी प्रकाशित करती हैं। वे अक्सर JUGAO जैसी कंपनियों और उनकी प्रगति के बारे में प्रोफाइल दिखाते हैं। ऑनलाइन बोर्ड और समूह भी लाभदायक हो सकते हैं। निष्कर्ष: अब आप यहां उद्योग के अन्य पेशेवरों से मोड़ने वाली मशीनों के बारे में प्रश्न पूछ सकते हैं और सलाह प्राप्त कर सकते हैं। वे उन मॉडलों के बारे में दिखा और बता सकते हैं जो उनके लिए अच्छी तरह से काम किए हैं।

स्प्रिंगबैक की समस्याओं से बचने के लिए उचित मोड़ने वाली मशीन का चयन करें

स्प्रिंग बैक की समस्याओं से बचने के लिए उपयुक्त बेंडिंग मशीन का चयन करना महत्वपूर्ण है। सबसे पहले, आकार मायने रखता है! विचार करें कि आप किस प्रकार की सामग्री को मोड़ रहे हैं। यदि आप मोटी धातु के साथ काम कर रहे हैं, तो आपको एक अधिक शक्तिशाली मशीन की आवश्यकता हो सकती है। भारी धनुषों के लिए यह मोटाई वास्तव में अच्छी है। JUGAO ऐसी मशीनें बनाता है जो विभिन्न मोटाइयों के साथ काम कर सकती हैं, जिससे आप हर बार सही मोड़ प्राप्त कर सकते हैं। अगला, नियंत्रण प्रणालियों पर विचार करें। उच्च-स्तरीय मशीनें कटिंग गहराई या सीएनसी (कंप्यूटर न्यूमेरिकल कंट्रोल) पर नियंत्रण प्रदान करती हैं। इस तरह, यदि स्प्रिंग बैक है, तो आप आवश्यक आकार प्राप्त करने के लिए सेटिंग्स के साथ प्रयोग कर सकते हैं। उन मशीनों की तलाश करें जो मोड़ का अनुकरण करने में सक्षम सॉफ्टवेयर से लैस हों। ऐसा करने से आप यह देख सकते हैं कि आपके द्वारा धातु को मोड़ना शुरू करने से पहले ही धातु कैसे व्यवहार करती है। प्रशिक्षण और सहायता भी महत्वपूर्ण है। एक अच्छी कंपनी आपके साथ सहायता करेगी और आपको स्थापित होने में मदद करने के लिए संसाधन प्रदान करेगी। JUGAO व्यापक ग्राहक सेवा और दो दिन का प्रशिक्षण भी प्रदान करता है ताकि आप अच्छी तरह से जान सकें कि मशीन का उपयोग कैसे करना है। अंत में, अपने बजट के बारे में सोचें। उन्नत मशीनें अधिक महंगी हो सकती हैं, लेकिन सटीक बेंडिंग और बचत समय उस लागत की भरपाई कर सकता है। इसलिए स्प्रिंग बैक को कम करने वाली बेंडिंग मशीन में निवेश करने से उच्च गुणवत्ता वाले भाग तैयार हो सकते हैं और लंबे समय में गलतियाँ करने की आपकी संभावना कम हो सकती है।

उन्नत सॉफ़्टवेयर बेंडिंग मशीन स्प्रिंगबैक नियंत्रण में कैसे सुधार कर सकता है

धातु को मोड़ना कई उद्योगों में, चाहे वह ऑटोमोबाइल, भवन या औद्योगिक मशीनें हों, एक महत्वपूर्ण भूमिका निभाता है। जब हम धातु को मोड़ते हैं, तो वह हमेशा उसी आकार में नहीं रहती जिस आकार में हम उसे मोड़ते हैं। इसे स्प्रिंगबैक कहा जाता है। स्प्रिंगबैक इसलिए होता है क्योंकि धातुओं में एक अंतर्निहित प्रवृत्ति होती है जो मोड़ने के बाद सीधी होने का प्रयास करती है। बेंडिंग मशीनों में उन्नत सॉफ़्टवेयर इस समस्या को हल करने में बड़ी मदद कर सकता है। JUGAO ऐसी बेंडिंग मशीनें बनाता है जिनमें स्मार्ट सॉफ़्टवेयर होता है जो यह भविष्यवाणी कर सकता है कि स्प्रिंगबैक कितना होगा। यह सॉफ़्टवेयर उपयोग की गई धातु के आंकड़ों के साथ विशेष गणित पर काम करता है। यह धातु की मोटाई, धातु का प्रकार आदि जैसी चीजों पर विचार करता है। इन विवरणों को जानकर, सॉफ़्टवेयर मशीन को यह निर्देश दे सकता है कि अंतिम आकार को प्राप्त करने के लिए धातु को कितना मोड़ना चाहिए।

उदाहरण के लिए, यदि आप स्टील के एक टुकड़े को U के आकार में मोड़ना चाहते हैं, तो यह इतना मोड़ने की मात्रा की गणना कर सकता है कि स्टील कुछ मात्रा में वापस लौट जाएगा। इससे अंतिम उत्पाद सही आकार और आकृति में प्राप्त होगा। और JUGAO की मशीनें वास्तविक समय में मोड़ के कोण की भरपाई कर सकती हैं। “यदि धातु अपेक्षित तरीके से नहीं बर्ताती, तो मशीन तुरंत अपनी क्रिया में समायोजन कर सकती है। इस तरह ऑपरेटर को गलतियों की चिंता करने की आवश्यकता नहीं होती, और तैयार भाग बिल्कुल सही निकलते हैं। उन्नत सॉफ्टवेयर पिछले मोड़ने के कार्यों को भी रिकॉर्ड करता है। यह प्रत्येक कार्य से सीखता है और समय के साथ बेहतर होता जाता है। इससे हर बार धातु को मोड़ने के लिए सर्वोत्तम परिणाम मिलते हैं। JUGAO प्रक्रिया के साथ, उपयोगकर्ता यह सुनिश्चित महसूस कर सकते हैं कि उनके धातु भागों का मशीनीकरण बिल्कुल वैसा ही निकलेगा जैसा वे चाहते हैं।

विश्वसनीय मोड़ने वाली मशीनें जिनमें स्प्रिंगबैक नियंत्रण के कार्य हों, वे कहाँ से प्राप्त करें

यदि आपको एक अच्छी मोड़ने वाली मशीन प्लेट उदाहरण के लिए, यह जानना महत्वपूर्ण है कि धातु पर एक उचित परत होगी और बीयर के बाद कोई स्प्रिंग बैक नहीं रहेगा। कई मशीनें हैं, लेकिन सभी अपेक्षित रूप से काम नहीं करतीं। JUGAO भरोसेमंद बेंडर प्रदान करता है जिनमें स्प्रिंग बैक प्रबंधन क्षमता होती है। आपको मशीनों में सर्वश्रेष्ठ खरीदारी करनी चाहिए। सुनिश्चित करें कि इन मशीनों के लिए आपकी दुकान एक ऐसे व्यवसाय की तलाश करे जिसका चार्ज बैक के साथ काम करने में अच्छी प्रतिष्ठा हो। आप उस कंपनी के साथ जाना चाहते हैं जो गुणवत्तापूर्ण मशीनें बनाने के लिए जानी जाती है, क्योंकि आमतौर पर उनके पास बेहतर सुविधाएँ और समर्थन होता है।

आप JUGAO मशीनों के माध्यम से उनकी वेबसाइट पर जाकर या उनकी बिक्री टीम से संपर्क करके खोज सकते हैं। वे विभिन्न मॉडलों और विभिन्न विशेषताओं के साथ काम करने के तरीकों की तुलना में आपकी सहायता करेंगे। अन्य उपयोगकर्ताओं की समीक्षाओं और गवाही को पढ़ने की सिफारिश भी की जाती है। जिन लोगों ने मशीन का उपयोग किया है, वे आपको अपने अनुभव के बारे में बता सकते हैं और आपकी स्थिति के अनुरूप सही मशीन के चयन में सहायता कर सकते हैं। व्यापार प्रदर्शनियों और उद्योग कार्यक्रम भी मशीनों को खोजने के लिए उत्तम स्थान हैं। इन कार्यक्रमों में आप मशीनों को कार्यान्वयन में देख सकते हैं और कंपनी के प्रतिनिधियों से प्रश्न पूछ सकते हैं। यदि आप यह निर्णय लेने का प्रयास कर रहे हैं कि क्या यह आपके लिए सही है, तो कभी-कभी मशीन के कार्य करने के तरीके को देखना सहायक होता है। और किसी भी विशेष प्रस्ताव या छूट के लिए भी सावधानी बरतें जो आपको पैसे बचाने में सहायता कर सकते हैं। एक बेंडिंग मशीन एक अच्छा निवेश है, इसलिए उसे खोजने के लिए आपका शोध करना लायक है जो आपके लिए सबसे उपयुक्त हो।

स्प्रिंगबैक क्षतिपूर्ति रणनीतियाँ - अपनी बेंडिंग ऑपरेशन्स से अधिकतम लाभ प्राप्त करने के तरीके

संगठनों को अपने बेंडिंग ऑपरेशन में जितना संभव हो उतना सफल होने के लिए स्प्रिंग बैक से निपटने के तरीकों को अपनाना चाहिए। इसमें एक प्रमुख दृष्टिकोण सही ढंग से इंजीनियर की गई बेंडिंग प्रक्रिया है। शुरू करने से पहले यह समझना महत्वपूर्ण है कि प्रत्येक स्थिति का क्या अर्थ है। जुगाओ मशीनें इस कार्य में उपयोगी हो सकती हैं क्योंकि विभिन्न प्रकार की धातुओं और बेंड के लिए सेटिंग्स को याद रखने के लिए उन्हें प्रोग्राम किया जा सकता है। इससे ऑपरेटर को नौकरियां बदलते समय सही मापदंडों के साथ मशीनों को त्वरित रूप से सेट करने में सक्षम बनाया जा सकता है।

एक अन्य दृष्टिकोण अंतिम उत्पाद के होने से पहले परीक्षण करना है। आप यह देखने के लिए एक नमूना मोड़ बना रहे होंगे कि आपका भाग कैसे मुड़ता है। इस तरह आप स्प्रिंग बैक को माप सकते हैं और मशीन की सेटिंग्स में समायोजन कर सकते हैं। परीक्षण की यह अवधि महत्वपूर्ण है क्योंकि यह अंतिम भागों को गुणवत्ता मानकों तक सुनिश्चित करने में मदद करती है। एक अन्य महत्वपूर्ण बात यह है कि कर्मचारियों को मशीनों को संचालित करने और स्प्रिंग बैक को समझने के लिए प्रशिक्षित करें। जितना अधिक श्रमिक समझते हैं कि मशीनें कैसे काम करती हैं और क्या उम्मीद करनी चाहिए, उतनी कम गलतियाँ वे करते हैं और परिणाम उतने बेहतर होते हैं।

अंत में, मशीनों के लगातार रखरखाव की मेटल पाइप बेंडिंग मशीन सब कुछ सही दिशा में रखने के लिए यह महत्वपूर्ण है। जुगाओ मशीनें अत्यंत मजबूत होती हैं, लेकिन आपकी कार की तरह, नियमित रखरखाव और देखभाल भविष्य में अनावश्यक समस्याओं को रोक सकता है। इस तरह मशीनें अच्छी तरह से काम करेंगी और मोड़ने की गुणवत्ता उच्च बनी रहेगी। इन तकनीकों को अपनाकर कंपनियां अपने मोड़ने के संचालन को बेहतर और अधिक कुशल बना सकती हैं और अपव्यय को कम कर सकती हैं। इससे न केवल लागत में बचत होती है, बल्कि ग्राहक आवश्यकताओं को पूरा करने वाले उच्च गुणवत्ता वाले धातु भाग बनाने सहित कई लाभ मिलते हैं।

Table of Contents

- सटीक स्प्रिंगबैक सुधार के लिए अत्याधुनिक मोड़ने की मशीनें कहाँ प्राप्त करें

- स्प्रिंगबैक की समस्याओं से बचने के लिए उचित मोड़ने वाली मशीन का चयन करें

- उन्नत सॉफ़्टवेयर बेंडिंग मशीन स्प्रिंगबैक नियंत्रण में कैसे सुधार कर सकता है

- विश्वसनीय मोड़ने वाली मशीनें जिनमें स्प्रिंगबैक नियंत्रण के कार्य हों, वे कहाँ से प्राप्त करें

- स्प्रिंगबैक क्षतिपूर्ति रणनीतियाँ - अपनी बेंडिंग ऑपरेशन्स से अधिकतम लाभ प्राप्त करने के तरीके